Here is a great image from my Fall 2013 fashion shoot. You can see it in full here and also in my online shop here. This year my work is all made in a cashmere, viscose and merino blend using 2/24nm yarn. It has a very satisfying cosiness and loft to the resulting fabric. Purchase from my shop in september using the code SEPT10 and you will get 10% off. I love a clean and straight forward format for my photos so many thanks to Ian Ross Pettigrew for finding that photographic sweet spot. You may also notice that the website address is different....but the website structure itself is the same:) I might have to check on my blog links to make sure they all work so sit tight if you find there are link issues. You can also email me directly for a link issue or picture you are looking for. For those seeking for more technical information and sample ideas check out the two below. I will add more from my Italian magazines shortly as well.

0 Comments

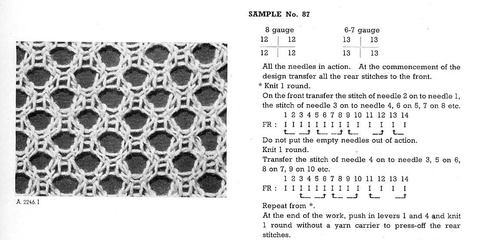

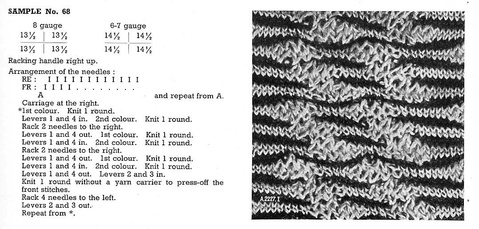

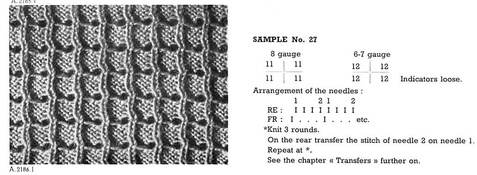

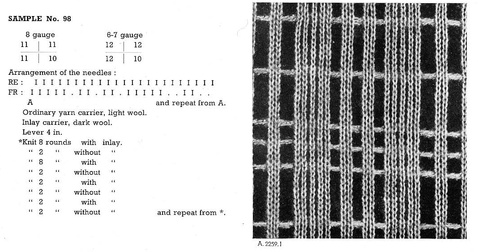

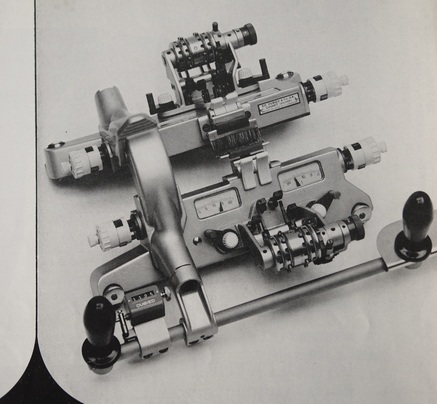

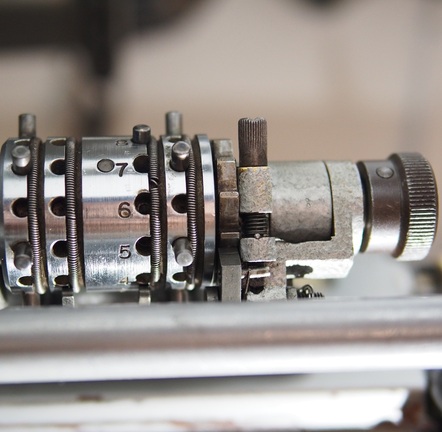

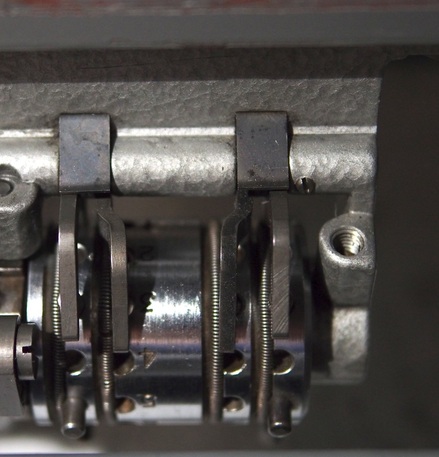

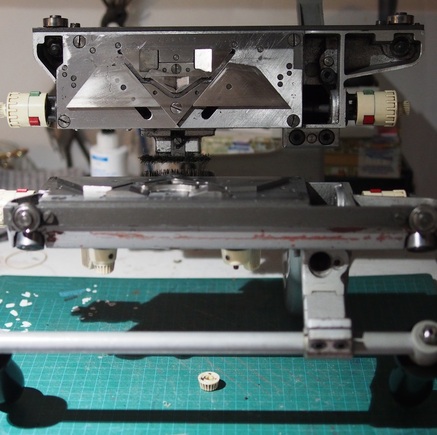

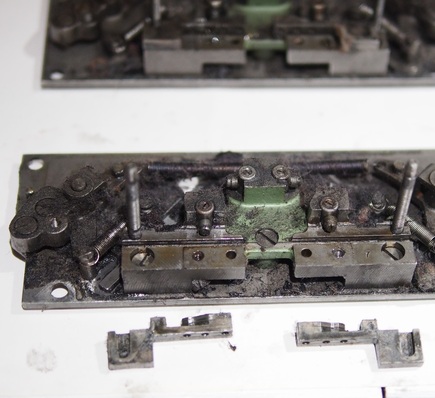

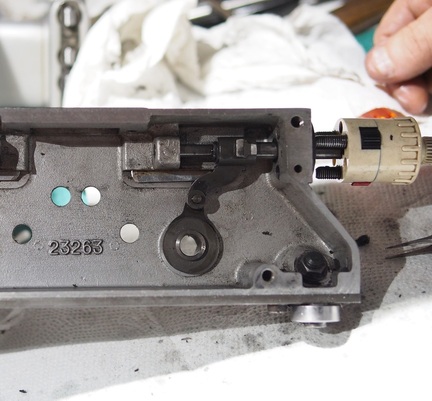

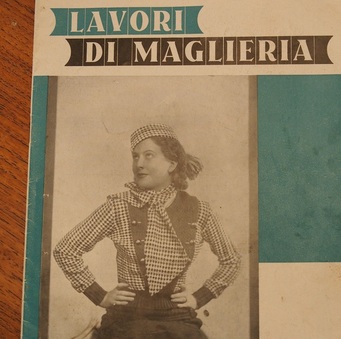

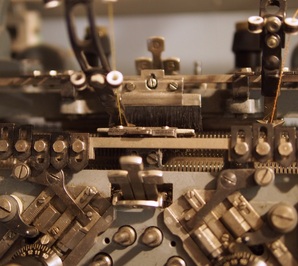

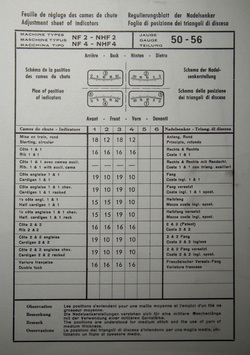

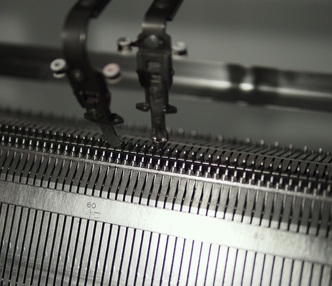

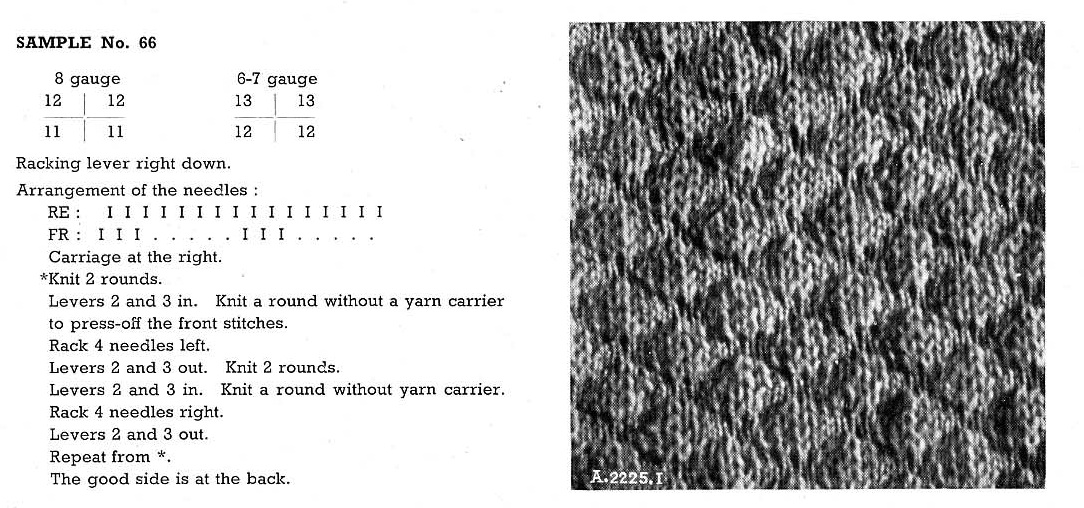

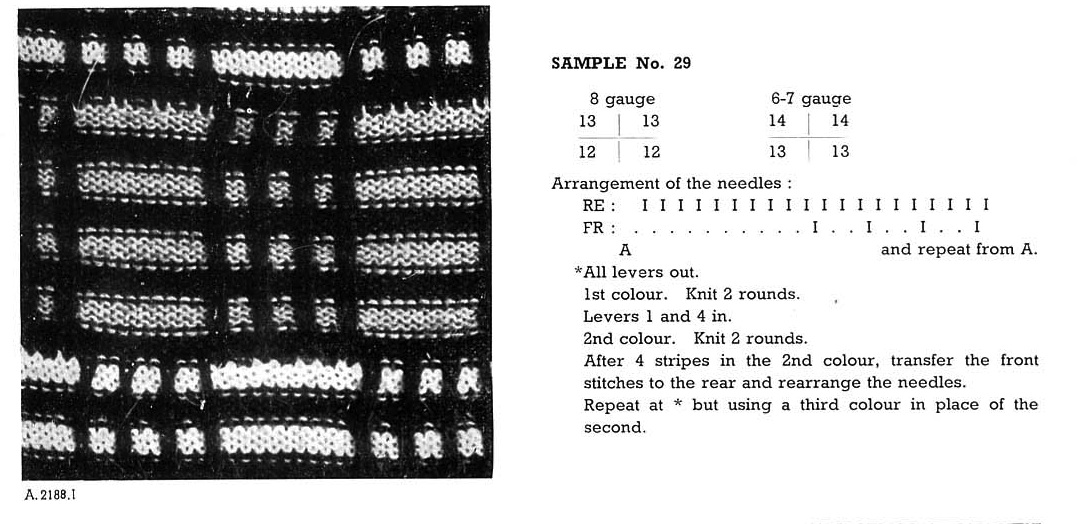

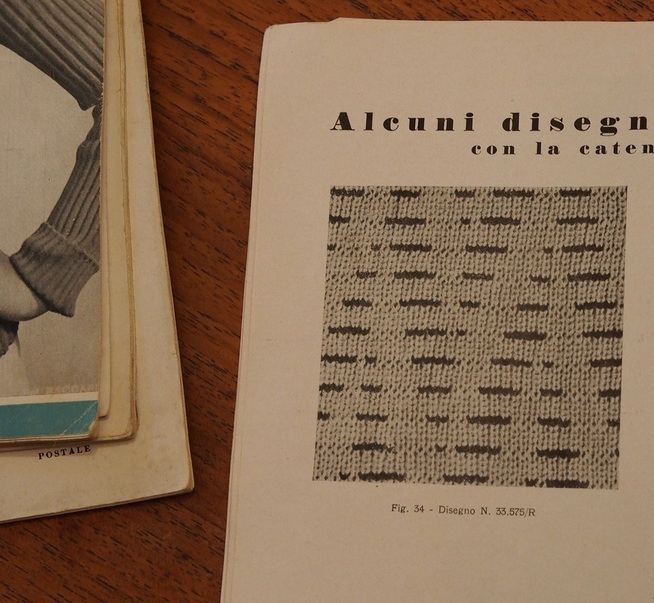

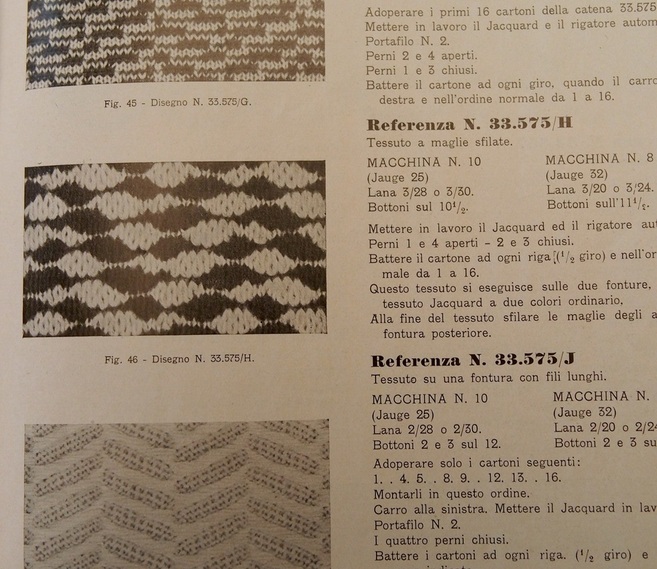

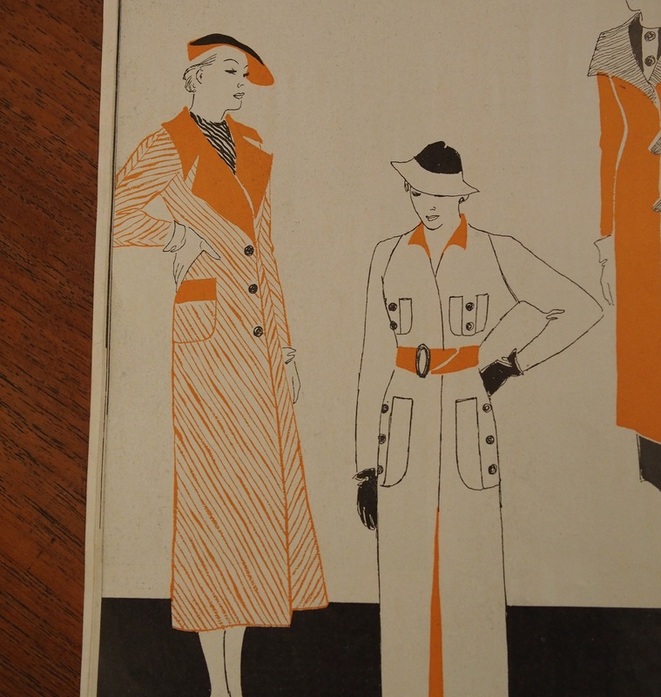

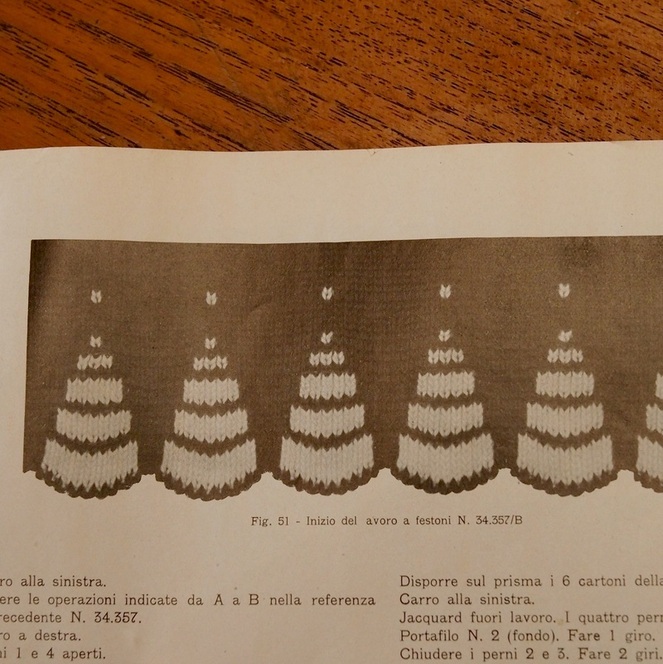

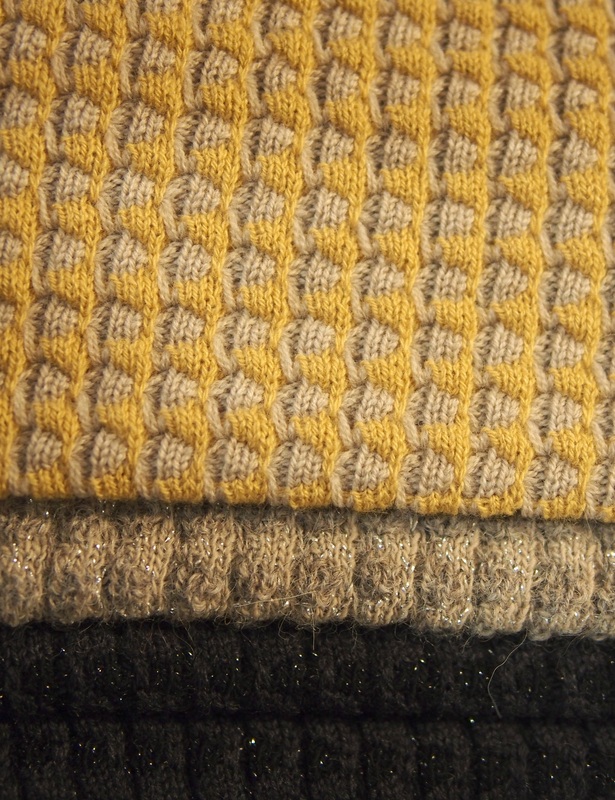

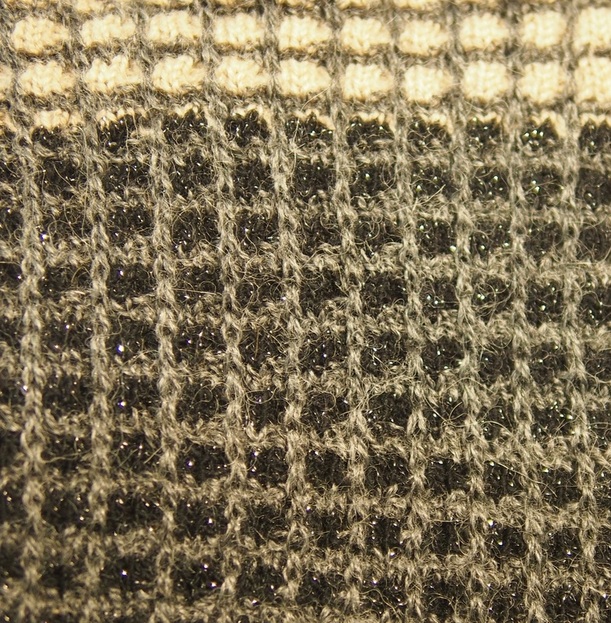

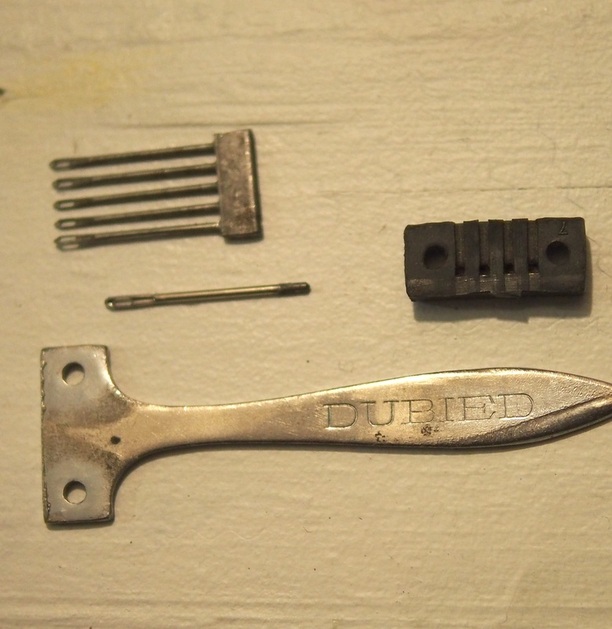

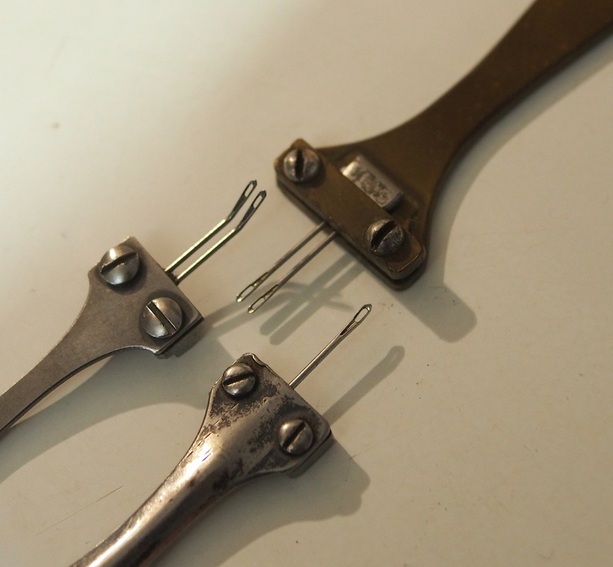

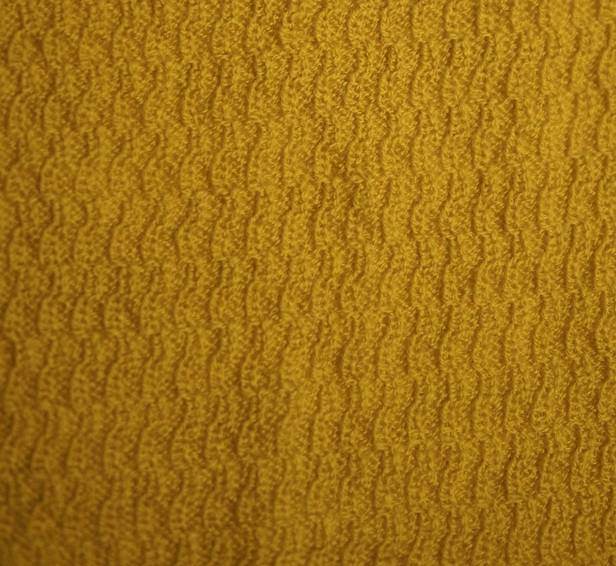

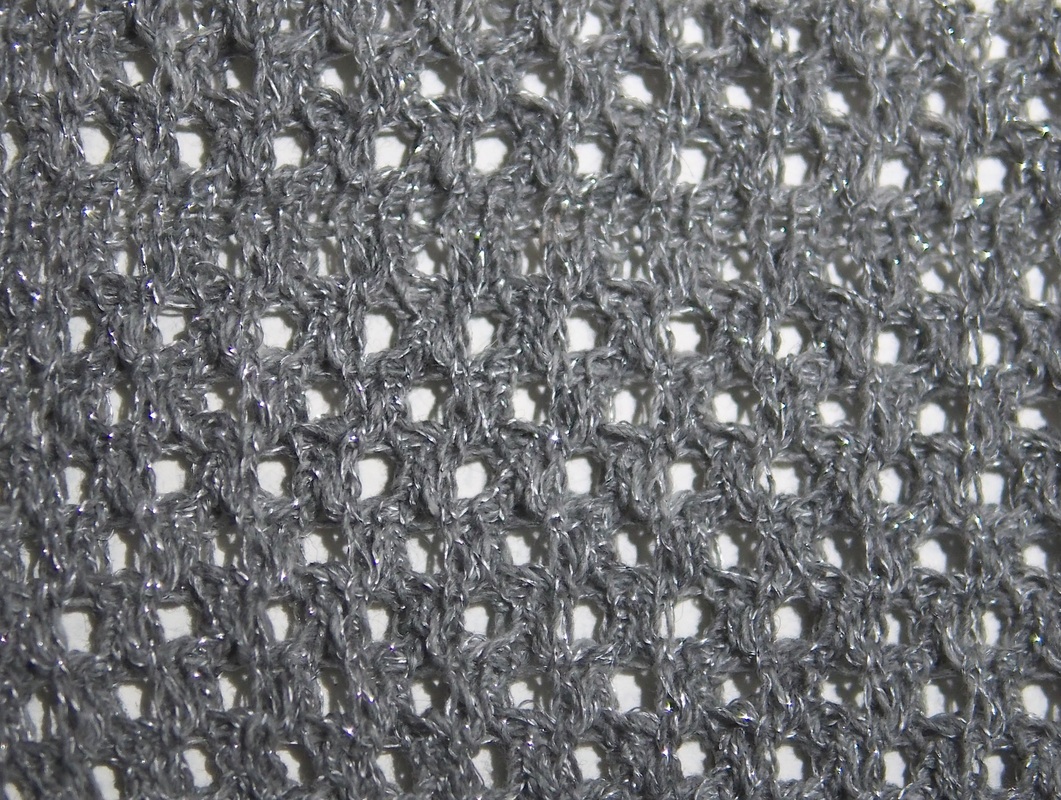

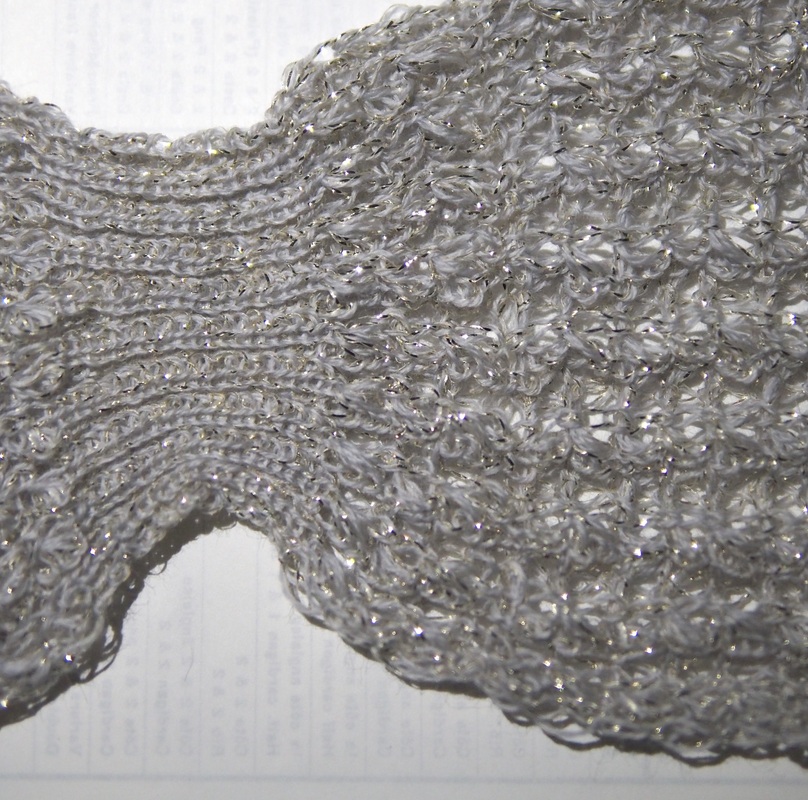

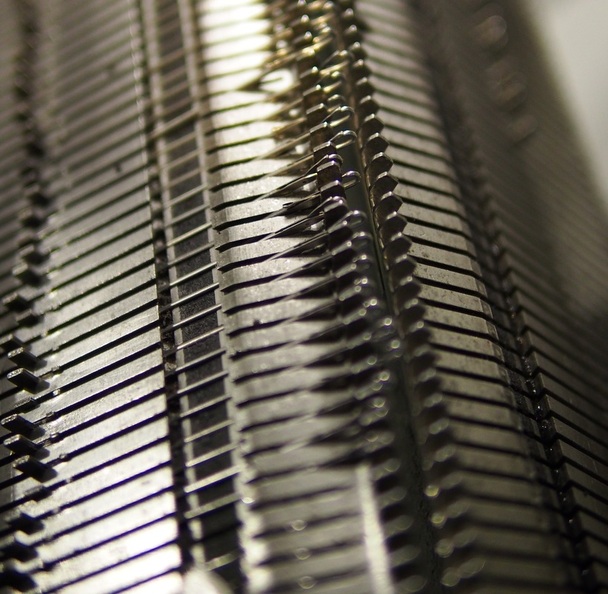

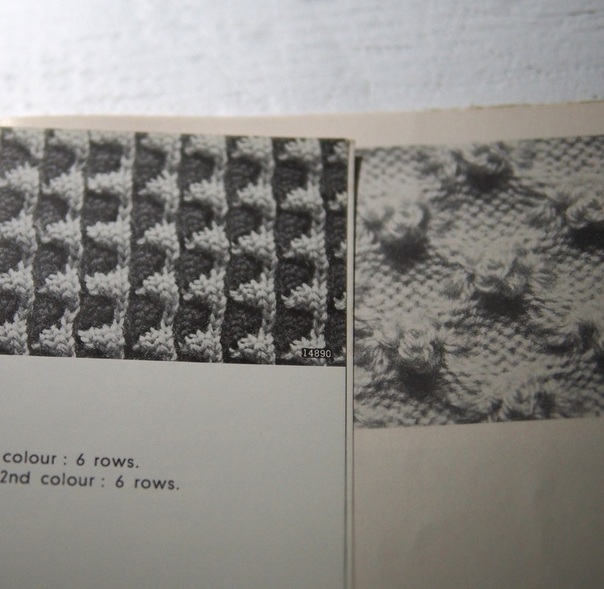

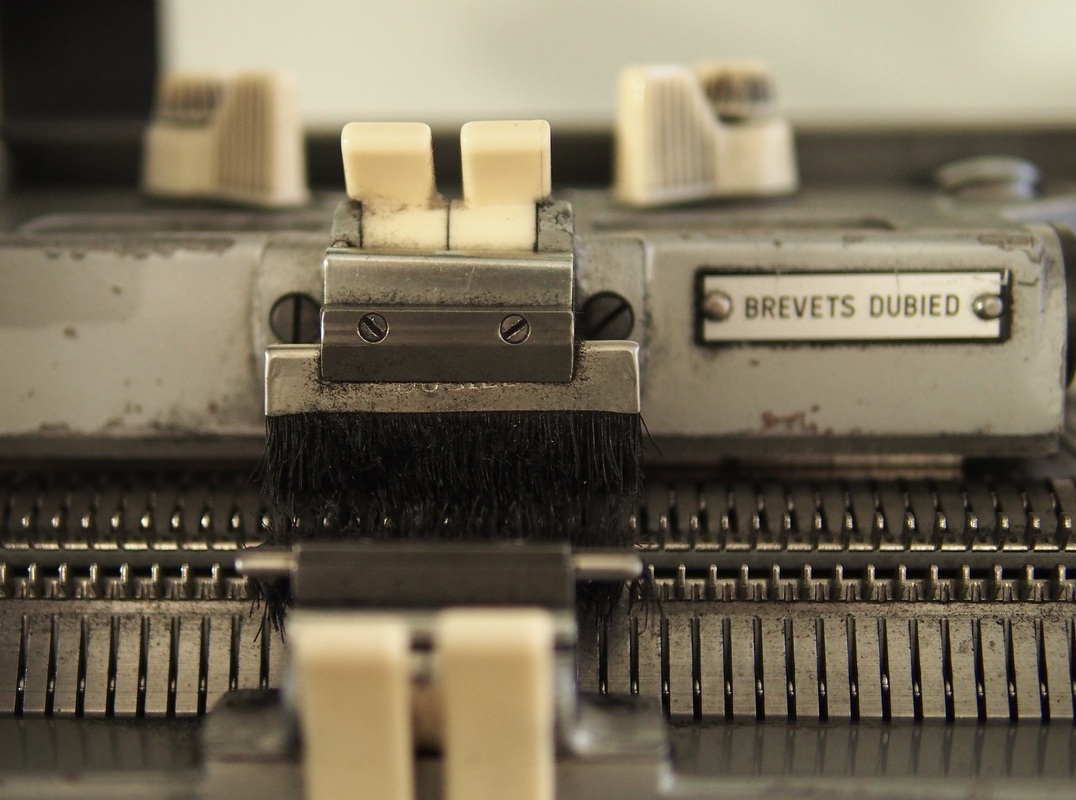

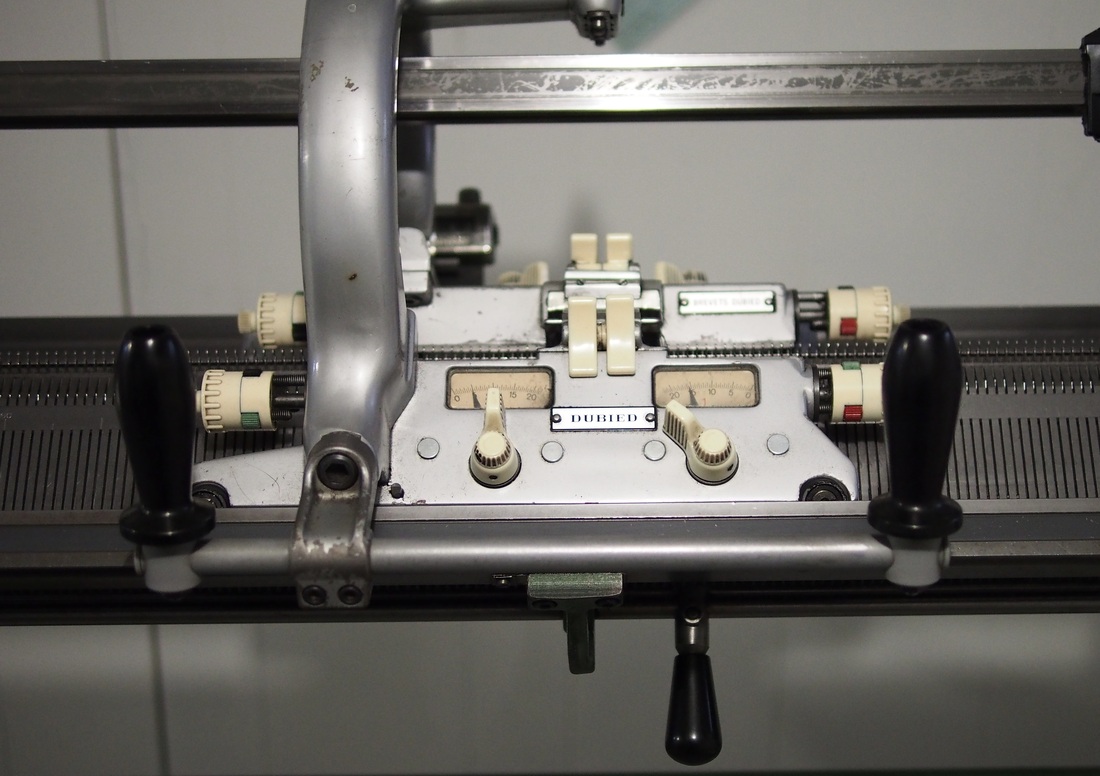

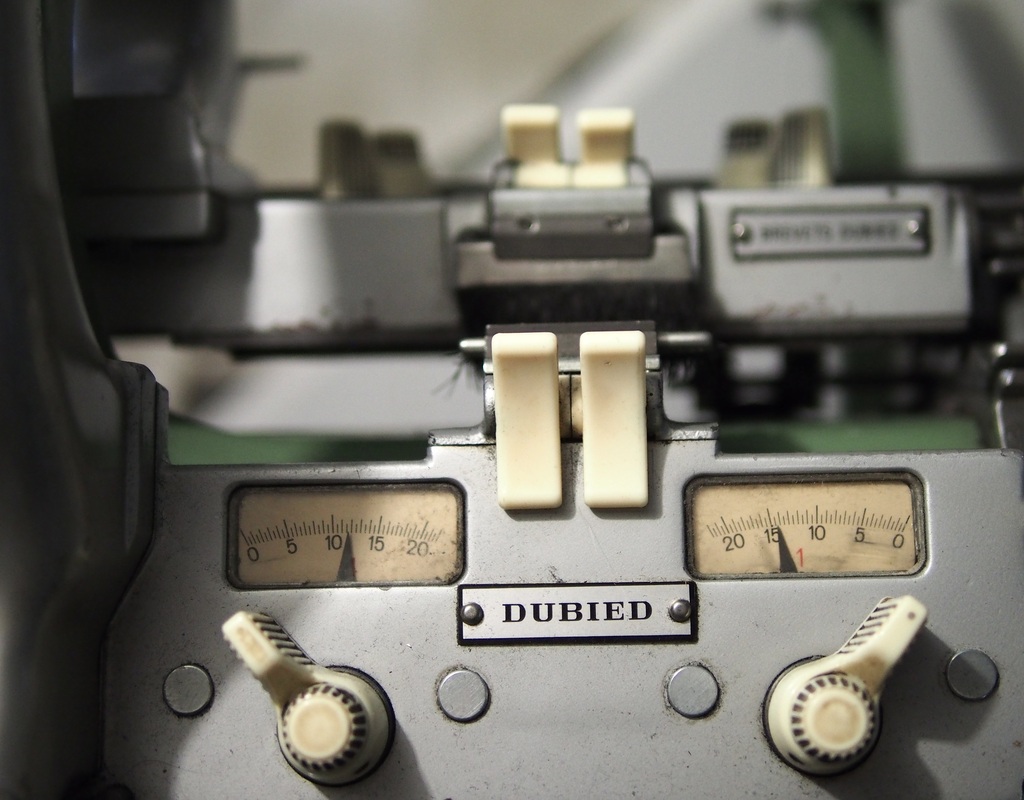

Recently Susan from Knitcloud contacted me and gifted me with an English version of an Italian language Dubied pattern book I already had (thank you Susan!). Translating from the Italian only goes so far and resulted in some rather confusing wording. I've decided to post some of the instructions and patterns as they are so charming.  This pattern book is meant for early low butt double bed machines so there are no high/low butt combinations. Still one can use, adapt and transform the basic format of these patterns in endless ways.  For clarity, when the instruction say "levers" in or out, what it is talking about are your cams which change from rib to tubular. So when a lever is out it is in a rib formation and when it is in, it is in a tubular formation. So if you look at the sample #68 it is alternating tubular and rib as well as racking the beds. Such an interesting pattern!  For those so inclined to use them, I do think the patterns speak for themselves. You can click on each one for a larger image and print/ save as needed. I will be posting them to my wiki for further ease of use. Earlier I talked about an Autocam Part 2 posting, and it is coming, but I am concentrating on finishing what has turned out to be a tricky Fall 2013 collection. So once I have that completed I'll put out some information on the Autocam. I do think this format of pattern posting is quite fun too so I'll be mining some of my books, notes and antique magazines for more!  My search for sustainable design and technology, has over the years led me both backwards (in technology) and forwards in terms of sustaining my own design practise...a practise rooted in analog, non powered, and intuitive approaches. This has slowly led me to explore knitwear machinery as an alternative to modern textile technology despite my roots in apparel design and textile printing. When I purchased my MM Dubied, a simple machine from the 1930's, it came with some 1954 editions of the Italian magazine "Estate, " in the back it featured advertisements for the Discam and the Autocam. When I graduated to the more complicated NHF4 Dubied I realized that the odd contraptions in the advertisements could help me speed up pattern selection, all without having to learn complex computer programming or buy expensive software. Pattern selection on these manual machines requires mental counting, time consuming hand toggling actions and a high degree of concentration so you don't lose your place. This is where Autocams come in.  Autocams are drum pattern devices that attach in pairs to the Dubied or Santagostino carriage, they modify stitches much like a punch card does. Discams are pattern devices based upon the disk format. They hold less information than autocams but operate based upon the same principle. The autocam is a drum with pegs of different sizes and positions which rotates one stop like a typewriter. For every pass of the carriage, cams are selected via fingers, also much like typewriter keys which change cam positions. For me there is an imagery format mashup of player piano drums, music boxes, machine knit and computer punch cards, typewriter selectors and clock gears. These formats were such logical straightforward approaches to the problem of mechanical selection. Their fall from favour was a side effect of the technology revolution but also major changes in fashion. See Sandy Black's book: Knitting: Fashion, Industry, Craft for more on this.  So why is this a Part 1? Well, I just recently installed an Autocam after spending some time with my very knowledge dad Edmund, who is a clockmaker. He helped me gut, clean and install the necessary parts into a Dubied carriage. Part 2 will be about using and changing the pegs!  The autocam rides on the carriage top, but it also requires longer cams so that the fingers can push select the cams. That is why we had to gut the carriage: to replace the cams and add fittings for securing the autocam.  Here's the underside of the carriage before it is stripped down.  Here's the very dirty interior of the carriage. I was shocked at all of that fluff and grime! Eww. Obviously we cleaned it up using a toothbrush and some gasoline and it looked much better.  Here's the completely gutted carriage. We are reassembling the tension assembly. We had to take it apart because the new cams are physically linked to parts of the tension.  Here the new washer has been installed for the longer cams and it has been linked to the tension assembly.  And here the Autocam has been screwed onto the carriage. The new cams need to be fitted where the old ones were and then the cam plate can be screwed back onto the underside of the carriage.  I hope this wasn't too geeky for you. I am excited about this contraption because I won't lose my place on patterns like the one to the right. It also means that really complicated patterns which require constant cam switching will be fun instead of frustrating.  I don't know about you but instructional manuals are pretty thin on the ground for manual industrial knitting. The manuals I do have discuss beginning work by creating a provisional cast-on. I always found this a bit frustrating and time consuming but I could see the logic in wanting to reduce the stress the first row endures weighted to the cast-on comb. In April while I sat watching a veteran knitter it dawned on me that she was creating her edges without any preamble or precautionary cast-ons. When I asked her about temporary cast-ons she dismissed my question. So I set about developing some edges which exploited tension changes and bravely experimented with weight or lack of weight on the comb to create a more time efficient approach. I developed: a picot edge and welt (this one is pictured below), a picot edge and welt for necklines, a firm racked edge and welt and a picot edge with rib. These basic edges which work for Dubieds and Santagostino's in combination with a cast-on comb and weights, but without any temporary cast-on. The short explanation (without getting too technical) is to rib cast-on only selecting high butts (or manually select particular needles), this pulls in the cast on edge. Then when you select all of the needles in combination with a 1 needle rack, tubular welt knit or rib you can come up with very tidy borders. Without slecting high butts during the initial cast-on and keeping tension quite tight, my edges were very sloppy looking. I also wanted to post this video on casting off. Amy Lawrence kindly gave me permission to show her video and because I am a bit of a futz with technology I am just providing a link. Amy's knitted jewellery work is fantastic and her videos are always well thought out. Check it out!  I have also added gauges charts for stitch structures to my knitting wiki here. The knitting wiki is an ongoing project in which I hope to add meaningful content specifically related to manual industrial knitting and its history. For now there are some intriguing punch card and cam patterns as well as the gauge charts. Also pictured are some production samples for Fall 2013. These knitted pieces are intended to reflect my interpretation of knitwear as something more tailored, refined and modern. So you will see lapelled cardigans and slouchy jackets with fitted sleeves as well as the mittlets and gloves from previous years. Its been a very busy and exciting month developing work in my studio, perhaps so exciting that at times I had trouble putting down the yarn:)   This final picture although rather rough, shows a new technique that I was shown to me by the veteran knitter I mentioned previously. I thought it might be of interest to others:) This eyelet with increases combination creates a nice bias effect seen in vintage knits. To create it you make a tube and increase stitches on one side of the tube. So you cast-on, then knit a tube for 6 rows, then increase one stitch on the left side of the front bed, then knit 6 more rows and increase one stitch on the left side of the rear bed. By continuing to increase only on one side of the tube you end up with a cone shape which, once cut open reveals the eyelets and increases.  I found these lovely knitting magazines from 1934-35 and I just had to share them:) The style expressed in Lavori Di Maglieria shows an energy and movement in the swatch patterns which I find so charming and the colour palettes seem very contemporary.What is interesting to me is the way knitted fabric is used through a blend of somewhat tailored forms and cut and sew methods. Of course, rib banding is used to finish necks and edges but the combined result is knitwear that looks refined in a manner not always seen in contemporary knitwear. I should qualify that by saying refined knitwear may be seen from the output of computerized industrial machinery, but from the perspective of a crafts-person working in a more analog, manual way, these examples made on industrial flat beds are inspiring and heartening. These magazines may have served to showcase current fashion in knitwear but they also showcased new technology and knitwear advancements through the fashion. There are articles on Dubied MUT jacquard machines and later in the 1950's these types of magazines discuss Discam and Autocam carriage accessories for speeding up cam pattern combinations while knitting. I have amassed a small library of these magazines however I have not come across any beyond the 1960's. I feel this is connected to the rise of computerized industrial machinery in the late 1950's and the difficulties of artisinal knitted work competing against such speed as was found in the most advanced machines of the day. I hope you enjoy these images.  Since graduating from Ryerson's Masters program, life has been a mixture of returning to a more normal way of living (reasonable work hours) and setting up my work areas so that I enjoy returning to those spaces everyday. Here is a picture of one of my work stations with old maps, music and above all, good light for knitting. In the afternoon the light coming through the smallish windows is quite beautiful and bright, but otherwise I use huge halogen lights. This month has been all about developing exciting textures and knit swatches for my fall collection. The act of servicing and cleaning these machines helped, I think, in the process of getting to know how the cams and patterning combinations differ from the Santagostinos and other double bed machines. Below are some of my more successful experiments which are based upon Guilloche and tuck structures. These rib based structures are formed through the use of both beds of needles through cam position changes. You can also create Guilloche on one bed through augmenting cam position changes with racking. I find the format of the photo does distort the size and context of the knit swatches somewhat, but they are quite fine gauge.  This is a close up of my Santagostino 10 Gauge. It excels at creating very fine gauge tuck and jersey structures, so I am developing knit swatches for light weight all season cardigans. It is fairly obvious that, to create a cardigan, one must develop professional hems, ribs and edges so I developed some handy tools (by cannibalizing extra tools and needles from other machines) to speed up the hand work involved. These transfer tools allow me to move stitches from one bed to another to create hem and cardigan body combinations. I simply unscrewed and discarded the old stitch holders and cut apart ones corresponding to the correct gauge for my machine. Then I made sure to space the stitch holders the correct distance apart and screwed them securely in. Bending the tool ends helps prevent live stitches from falling off the end of the needle. For collection development, it has been really useful for me to think in terms of each machines limitations. By blocking out the strengths of a particular machine, stitch or yarn I can move forward without coming up against too many hurdles. For example my Santagostinos do not seem able to do the same Guilloche as the Dubieds. There is a half cam position which the Santgostino lacks. V-bed machines while wonderful are not jacquard or punch card capable therefore a certain degree of user ingenuity is necessary.  Here is one last image. My boyfriend and I took a long walk through Hamilton this morning to find the old Cannon Knitting Mill. It is a series of 5 buildings built between 1860 and 1950 which spun cotton, knitted curtains and all sorts of other items. It has several charming facades and entrances but otherwise its huge windows are boarded up. This particular corner is said to have originally been a hotel. I am really taken with the romantic and impractical idea of making it into a knitting mill again and fixing it up!  It's pretty fabulous outside in my corner of the world, but none the less I've been working away at studio housekeeping, acquainting myself with my new machines and ordering yarn. These cashmere/ lurex cones just came in and I love them! Below is a sample of how this yarn knits up. I like how each stitch is clearly defined. When knitted up in plain wool or angora, the springiness of the yarn, results in a less lacey look. A nice bonus which came with my machines are a series of gauge cheat sheets (like the one to the left) for refining particular stitch structures. For individuals just beginning on v-bed industrial knitting machines, finding the right gauge so you can start experimenting can take a long time and be really frustrating. At the top right it says Gauge 50-56 which is really Gauge 5-7. Charts like these are great for orienting your work and quickly working with tension formations so that later you can create customized charts of your own for particular yarns. I'll be placing them all in the Wiki section of my website as I upload them. I also have a facebook page I just started here. In the future I will be offering various sales and showing previews of my collections on that page. Deep cleaning my machines has gone really well. I special ordered new needles and a few parts from Scotland. As you can see from the photo below, the needles were well used and needed oiling and checking for wear. The needle beds also needed cleaning out so that the needles could run freely. Today after putting all the pieces back together I began swatching. It felt great to begin knitting and get a feel for the machines capabilities. I worked with 2/16nm Alpaca yarn creating some simple structures and hem edges. Tomorrow I'll try some Tuck structures and add some colour.

Short of taking an advanced knitting course, I wish there were better practical information for the knitter. There are quite a few older books for V-bed and Passap but language is inconsistent or incomplete. I feel sure that at the height of knitwears popularity that technical books were available in the industry. I would really like to get my hands on them!  Last week I found an ad for what I consider the Holy Grail of finds: several Dubied knitting machines in good user condition from a working shop. This company produced well finished, well considered knitwear designs from skirts, to coats, to fine sweaters and was in business for more than 50 years. If you read my blog, you know that I already have some Italian Santagostino's which I imported for no small sum. These Dubied's are Swiss, there is some debate as to which company makes the better machine. Each machine has well finished parts. I do prefer the Dubied carriage over the Santagostino. These machines do not create patterns via punchcards, instead cams inside the carriage are controlled via switches and these modify stitch formations. You can create rib knits, tube knits or flat knits, then from there modify that basic structure and then from there further modify that structure further by positioning the needles in certain configurations. One can knit Guilloche, Nopped, Cardigan, Variure, Ripple and many other knit stitches. These are classed as NHF4 knitting machines: N: rib and tube cams, F: cardigan cams, H: high and low butt needles, and 4: 4 yarn carriers.  This is a linker (or looper) , it attaches collars and rib bands to the body of the garment. It essentially stitches a chain stitch with yarn. It also joins shoulders and side seams. This one is powered and provides a very professional looking finish. Once I get some practice on it I will post some finishing techniques. Some of these photos document a "just moved in" state and they require some service, dusting and care. I hope you enjoyed the photos..... I've been a busy bee lately, completing a collection of clothes based upon fashion research. Focus was on early 20th century material production innovation in haute couture houses as response to social change. So there is a lot of handwork and complex stages of cutting, matching and fitting. The following photos are just a few from a recent fashion shoot, with more posted soon in my collections website section.

In other news, which is just as exciting...I am acquiring more industrial machines and an antique linker for professionally finishing and joining knitwear. An opportunity came up that was too amazing to pass up. Although these two subjects may appear divergent, my interest in high quality material production practises draws them together. Black's book "Knitting, Fashion, Industry, Craft" details fine knitwear construction practises in the early 20th century which orients knitwear along side haute couture sewing and lingerie production. I will be posting pictures of these new machines later next week. |

Anna is a Hamilton based knitwear and textile practitioner blogging about her collection development as well as pre-1950's knitwear technology.

Links

Emma Gerard Make something bookhou Iben Hoej krystalspeck workshop bespoke truckee amy lawrence designs Categories

All

|

RSS Feed

RSS Feed