|

Last September I drove out to an area north of Montreal and picked up a Vandercook 4 printing press. Its a proofing press that many use for letterpress.I have a strong background in textile design using silk screen printing and it was my idea to expand on that via lino and woodcut printing. It proved to be quite the undertaking (all disassembled 1600lbs of it) and in some ways very close to my work on hand flat industrial knitting machines. My first knitting machine was a real fixer upper and in turn so was this printing press. I know it inside and out.

I also learned I was suffering from production fatigue and the move to other media was really beneficial in understanding my love of knitting. I have since purchased more knitting machines, more equipment, more printing tables, books and supplies. As well Ive taken on some knitwear teaching and Im re-learning some tried and true techniques that perhaps I had forgotten. I think as artists and makers we can get caught up in the idea of staying with one medium but when we do one thing too much our complex brains seek out creativity and variety. Following that, this whole minimalist trend really doesn't sit well with my need to constantly collect, curate, edit and spit out new work. So I've come to terms with being a Maximalist.

1 Comment

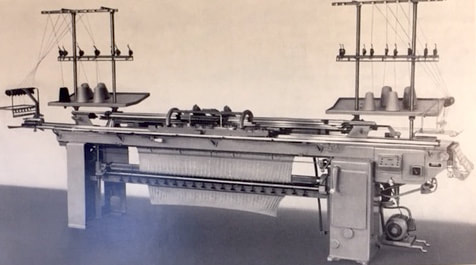

It has been a while since Ive posted about knitting. Why? Because Ive been spending a lot of time thinking about directions and production. Ive decided Im an analog girl at heart and the pursuit of fulfilling greater orders with a computerized knitting machine really doesn't help my pursuit of satisfaction and fulfillment in my craft. As a result I'm selling my machines. If you are interested in a gauge 8 Moretto NHF4 with Autocam, a gauge 8 Dubied Intarsia machine, a gauge 5 NHF4 Dubied with Autocam, a DUT Dubied gauge 8, a gauge 10 Dubied N4, or a gauge 7 linker from 1972. Let me know! I am clearing out my studio to focus on my drawing, printing and illustration. What you say? Yes, I trained as a textile designer printing and illustrating (as well as a fashion designer). Knitting was self taught. So I'm gearing my studio towards silk screening, letterpress and hot foil stamping in the future. I think this will be more sustainable for me. For me this is very exciting and I hope to show you the fruits of my labours very shortly! Contact me if you'd like to purchase or trade equipment for any machines or would just like more information.

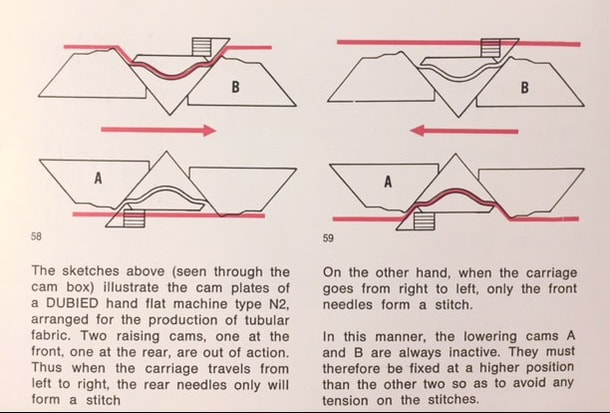

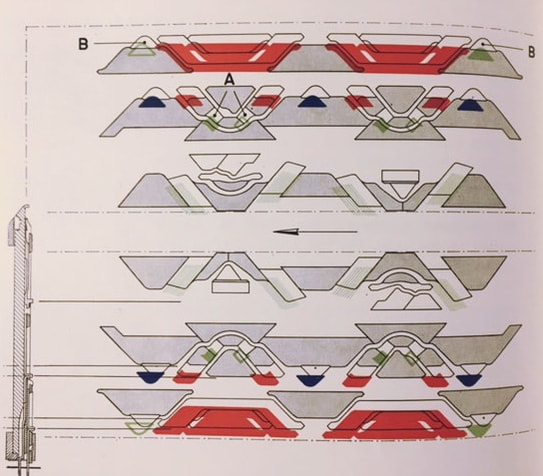

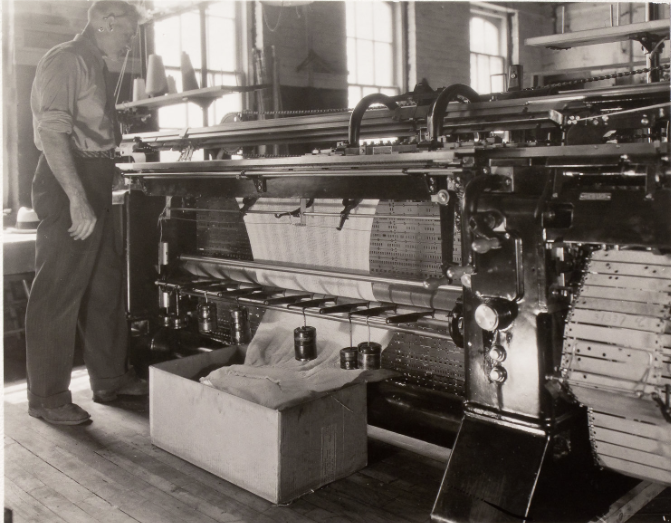

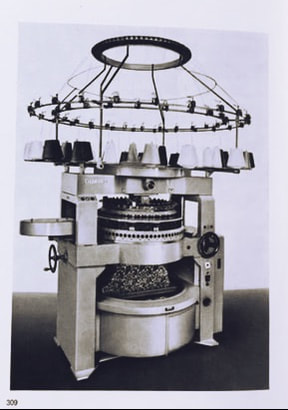

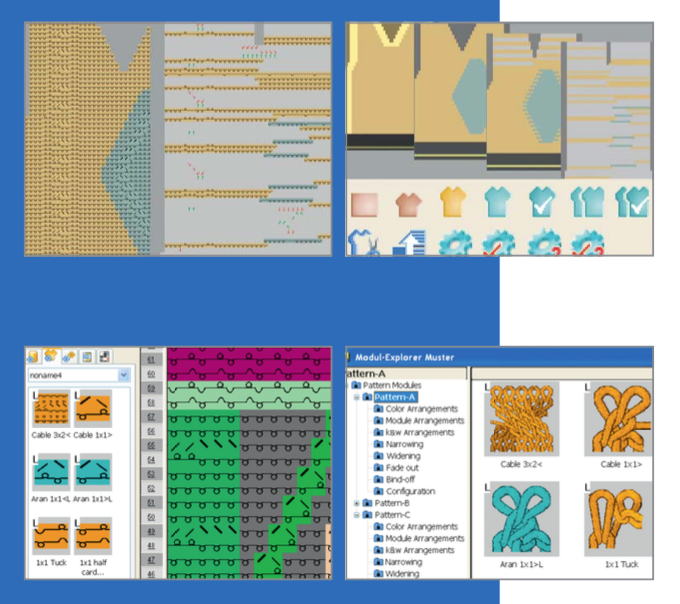

Im exploring the world of computerized knitting machines from a hand flat background and it can be very mystifying at times. I spent some years considering analog but motorized stoll/ shima/ dubied machines from the late 1970’s. These machines used punchcards, prism mechanisms and drums to create patterns (or direct the needles into pathways to create patterns). I have collected the Dubied DUT which is missing a key pattern device, I have a Moretto with a worn out motor and take down device (with auto cam!). I use this machine as a hand flat and it is so reliable. As well, I have the Super-8 mechanism (it has a habit of slipping though like a stripped screw so the pattern gets all jumbled up). The diagrams below show the basic difference between a Dubied N2 cam carriage and a more complex computerized one: there are more available paths for the needles to create more complex stitches. (Many of the diagrams are pulled from a book called "dubbed Knitting Manual. It is a hardbound book that examines the stitch structure of knitted pieces and explains it in structures similar to how modern knit software looks.) In terms of semi industrial machines that are also double bed there are (or were) the passap e6000, e8000 as well as the brother ck35. These 90’s era machines potentially have interface issues with software and modern computers. Venturing further into domestic machines the brother 900 series machines with a ribber attachment can accomplish many textures and patterns on the machines’ computer. All of these machines whether domestic or industrial have a maximum speed measured by ‘stitches per meter’ (or m/s) that is effected by: whether its motorized or not, the type of pattern produced, how many colours per row, the width and size of the piece to be produced and the gauge. Many modern industrial machines have a top speed of 1.0 m/s which is insanely fast. I think this top speed would be for a stockinette in one colour and only using one bed to knit. As you add more colours and complexity your speed will be reduced. Overall, my interest in industrial machines is about increased complexity and production. Right now I produce everything on hand flats which can take many hours. I love the feel and build quality of hand flats but not the speed. Some brands that make computerized machines are : Stoll, Shima seiki, Steiger, Protti, Universal, and Shine Star. Once you get into specialty machines there are ever more brands. There are sock machines, glove machines, toque machines, circular machines for mattress covers, industrial filters, shoes, and medical supports. But we are getting ahead of ourselves. This is about computerized machines that will do basic jacquards, basic programs and how to use them. Ive found some classes for Stoll here which is in a college setting in North Carolina. But really Stoll (and Shima Seiki) offer classes around the world in many major cities. For example, New York has a salesroom for Stool but they will also demonstrate the software for you. There are also comprehensive classes in Frankfurt, Germany. This week long class primarily exposes you to the M1 Plus software that builds files for Stoll machines then you knit out your piece on the machine. The program recommends that you have experience on hand flats before taking the class. If you look at knitting patterns for hand or machine, its about actionable steps in generally a grid formation. This program takes that concept to a higher level…with more actionable steps. To be continued.

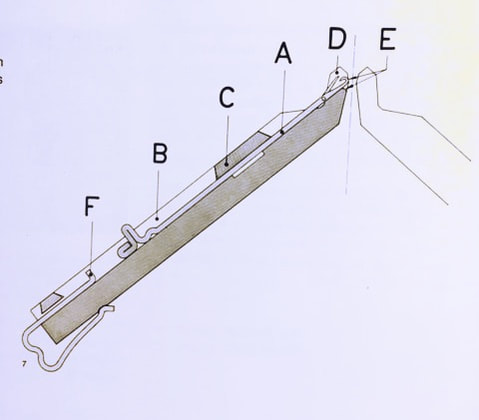

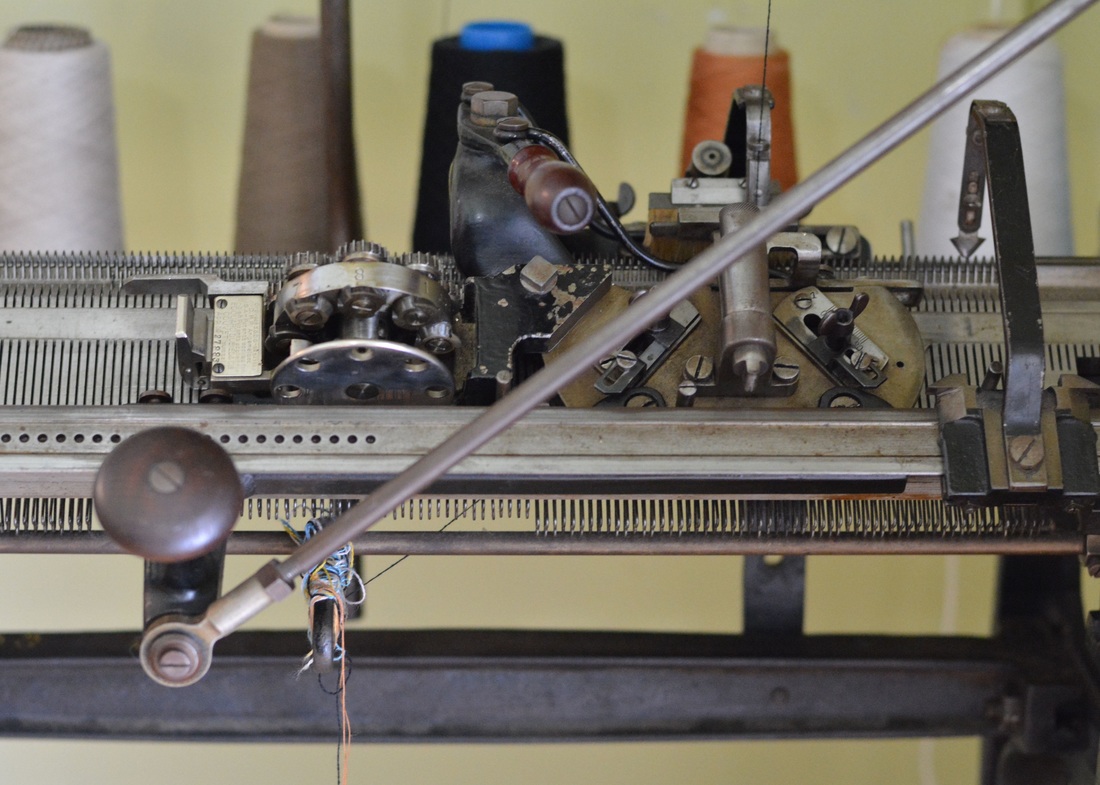

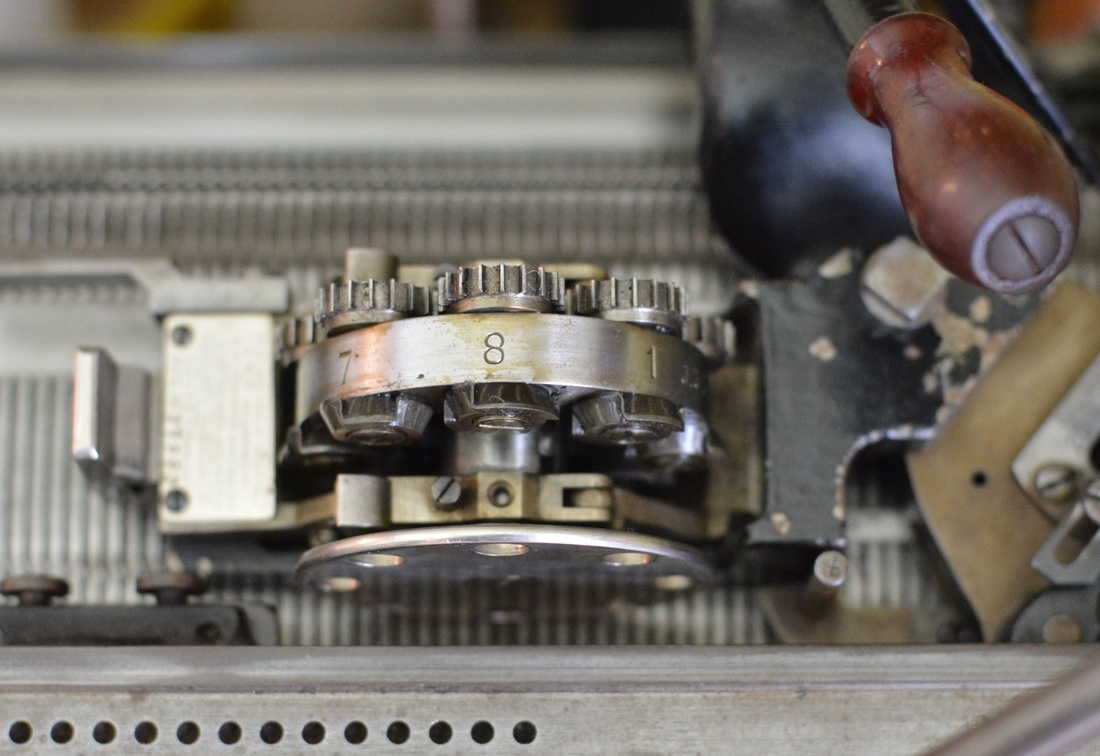

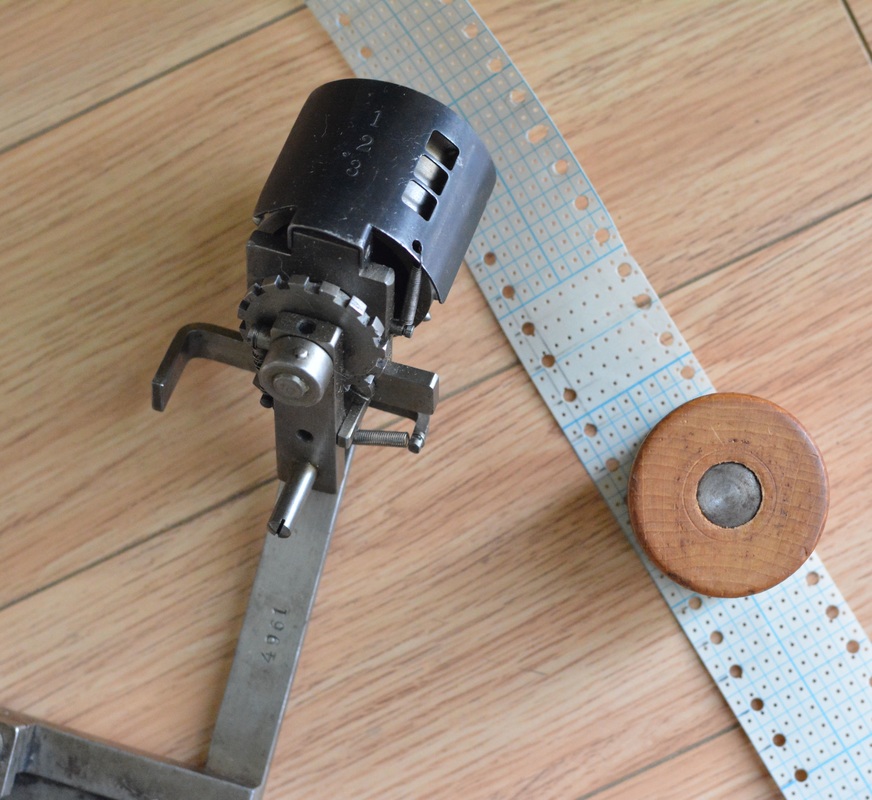

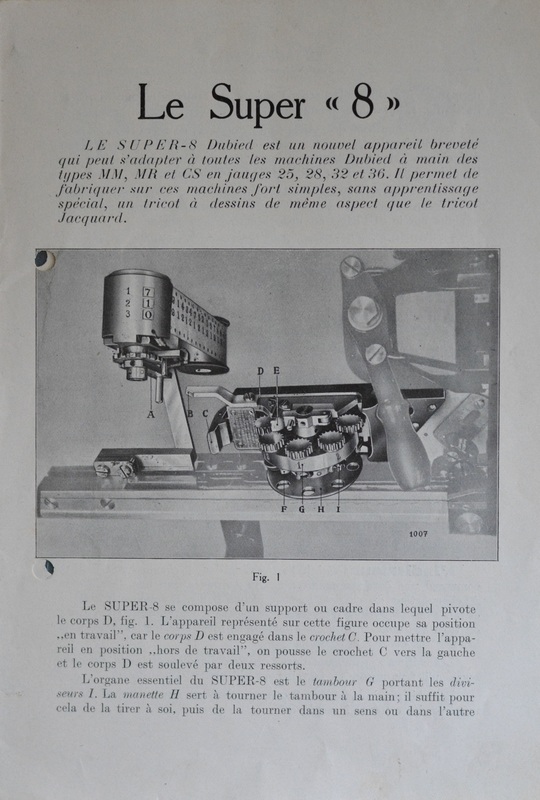

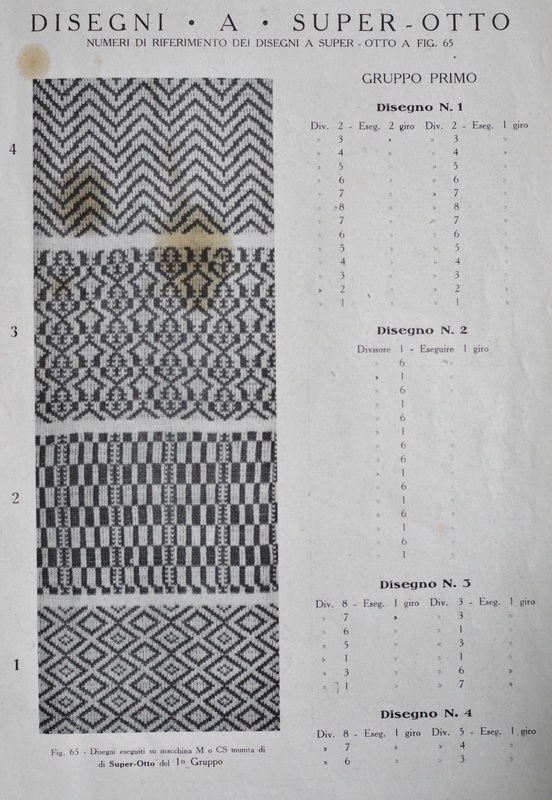

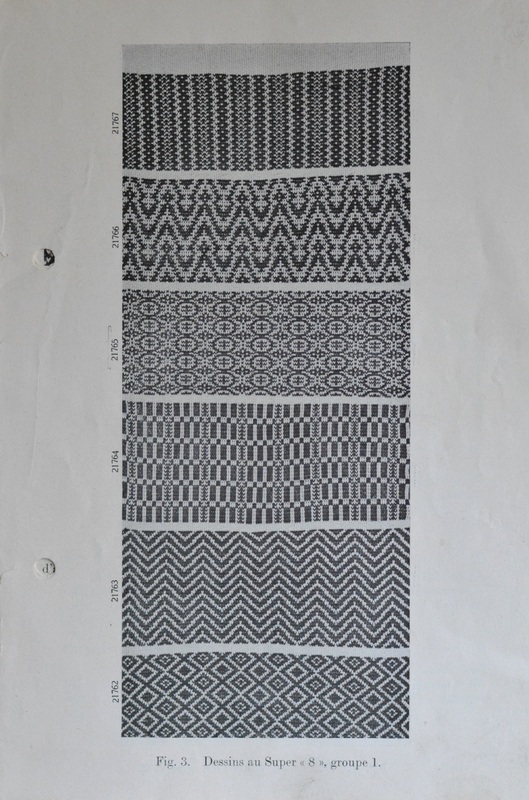

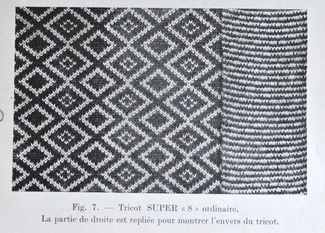

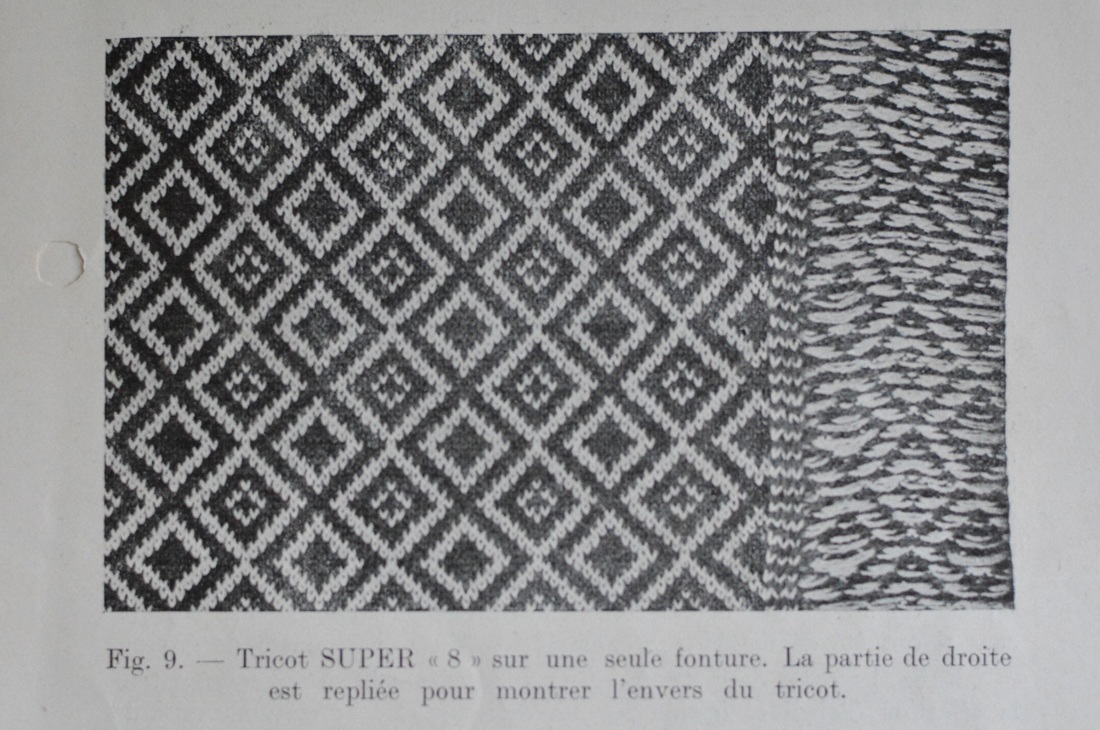

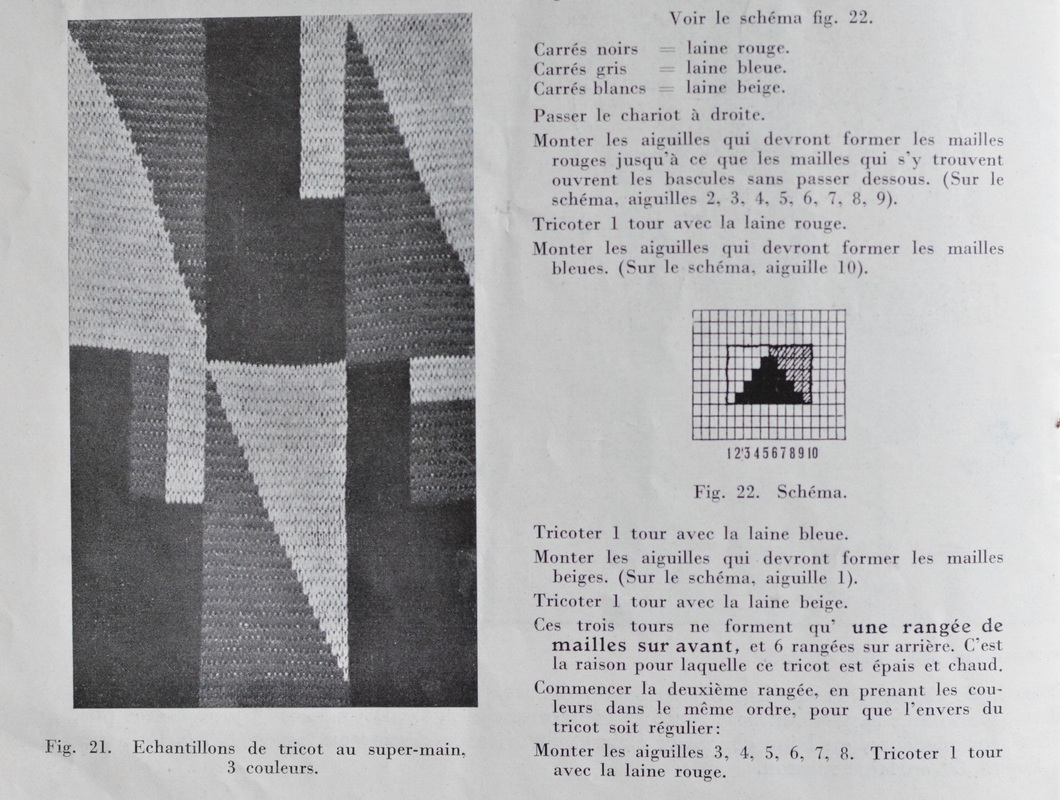

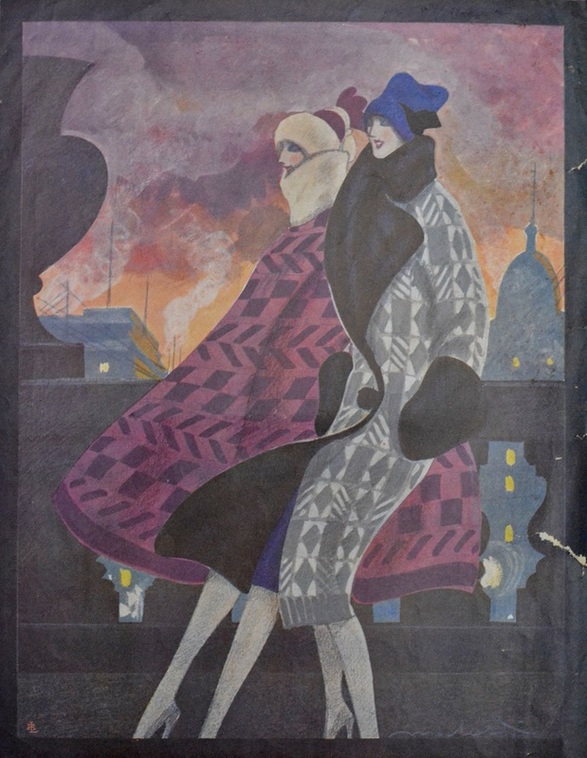

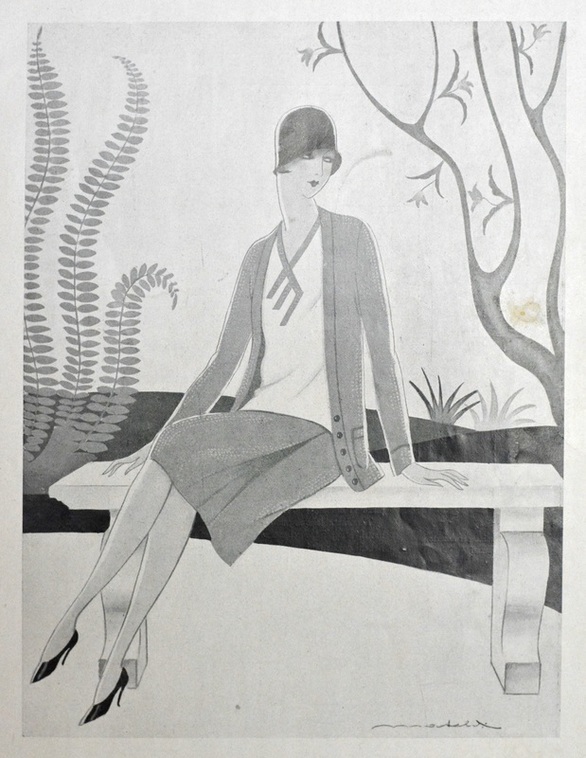

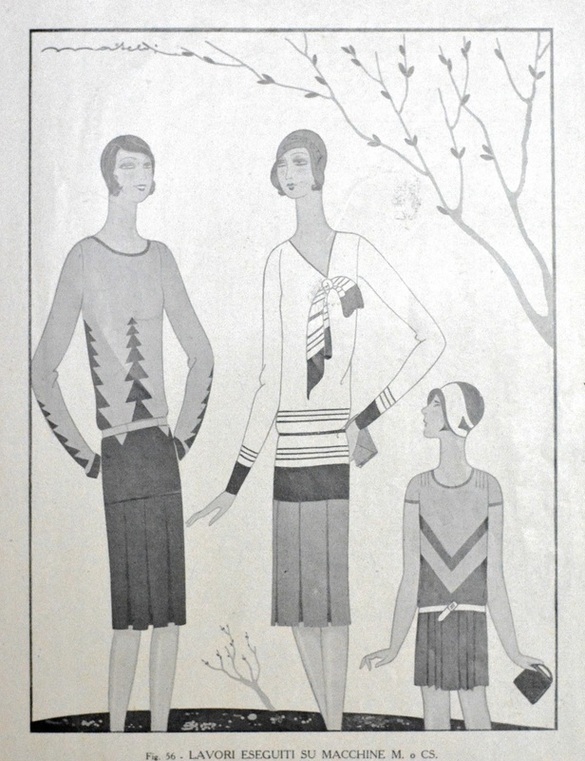

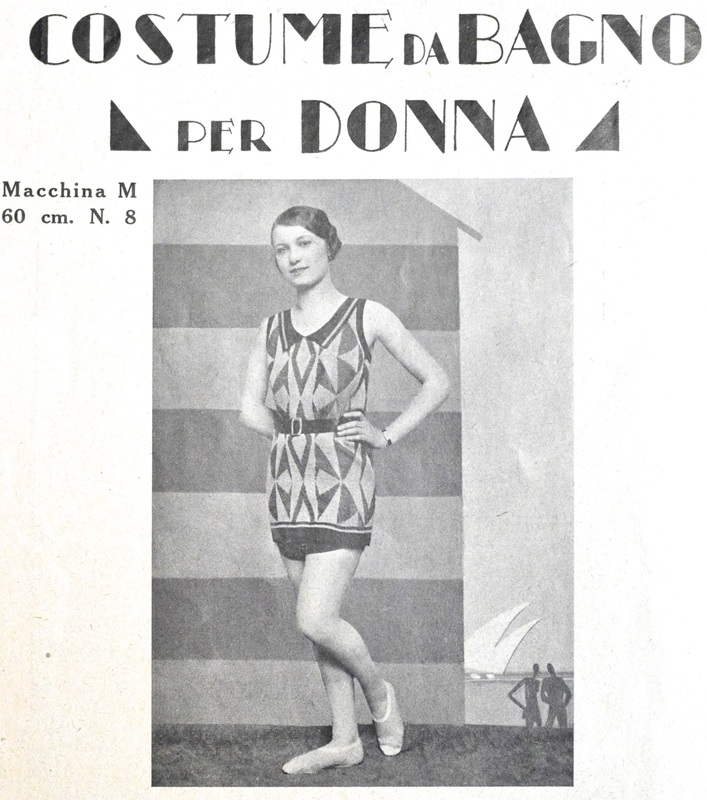

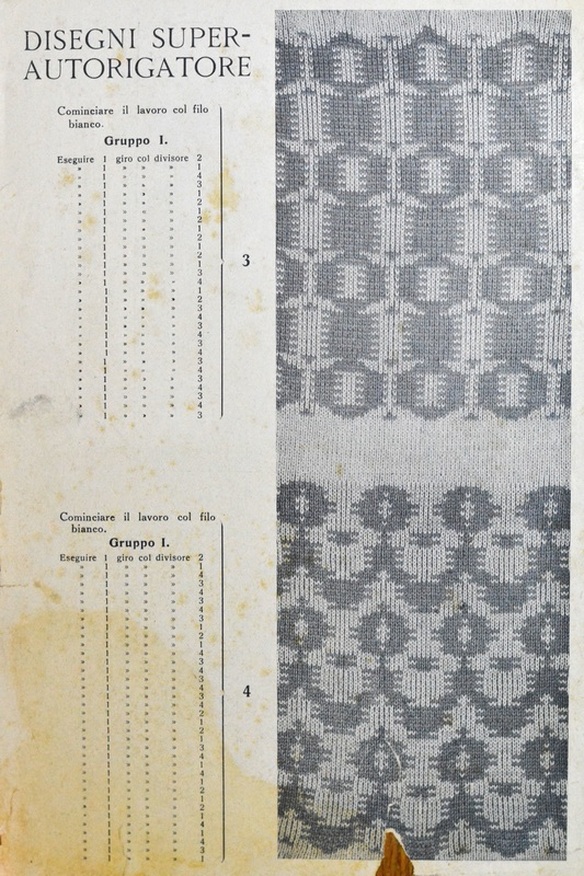

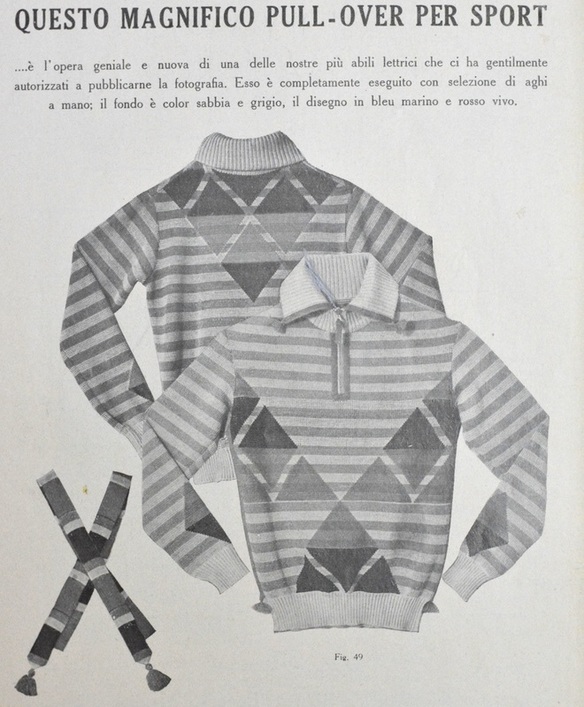

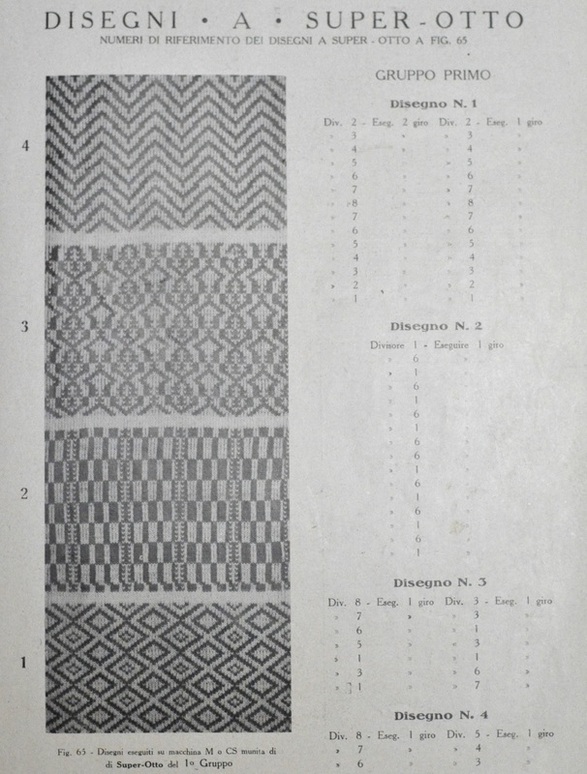

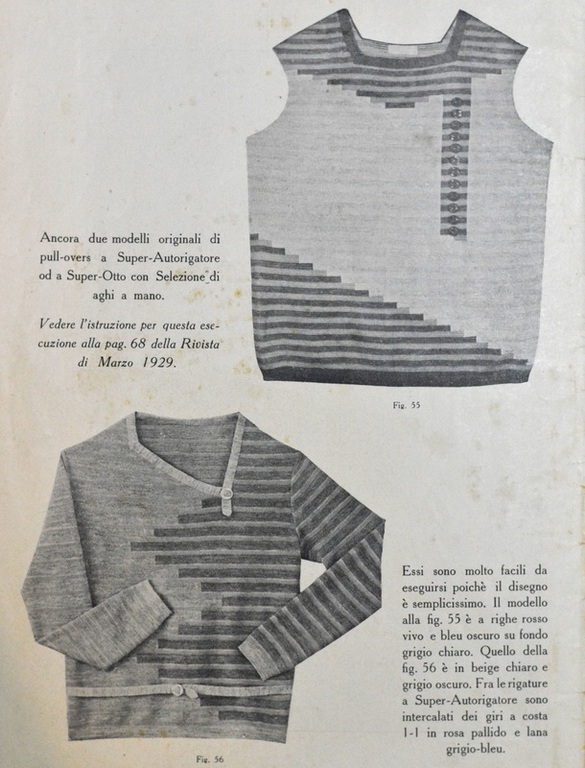

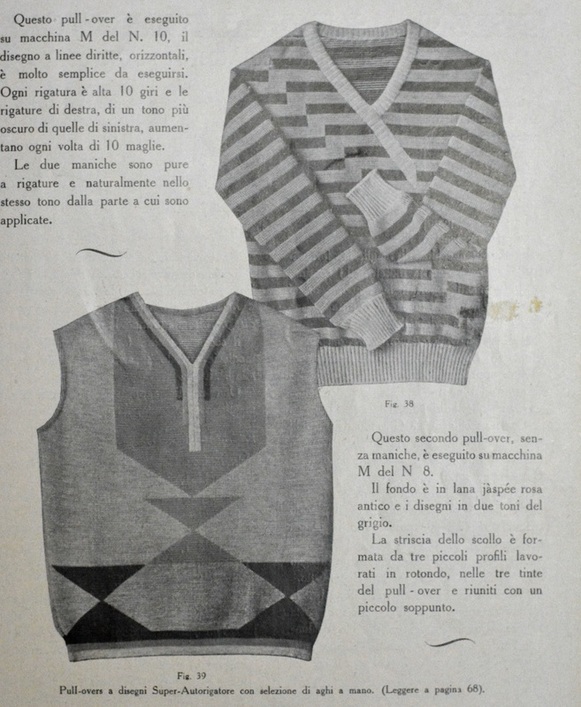

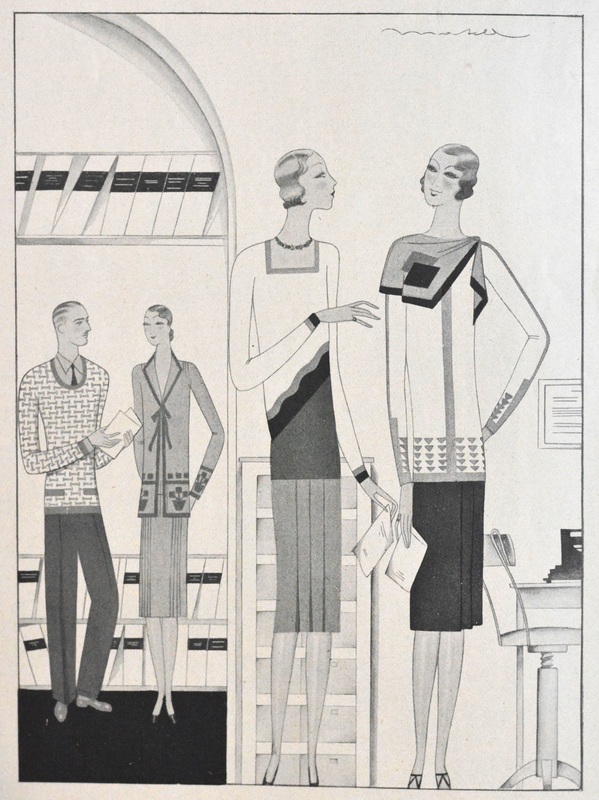

Ive been interviewed by Emma Smith from Black and Smith General Store. check it out here...2/9/2018  Its been a while since Ive posted. Lots of life events have gotten in the way. Im a home owner! I've got more machines! I've been flying all over doing craft shows! All the things have happened! Luckily things are starting to settle and I'll return to posting about knit geekery. In the meantime check out this great post from Emma Smith. http://www.blacksmithcountrygeneral.com/the-makers She and her partner have a wonderful shop and studio in the Ancaster/ Jerseyville area of Hamilton. She makes beautiful functional ceramics but also, curates textiles, prints, ceramics, wood and jewellery pieces in her shop. I recently acquired an old dubied machine with some interesting accessories I have never come across before. The accessories are pattern devices called the Super Auto Rigatore and the Super 8. Along with the pattern making device is a pattern reader which helps the user keep track of the repeating pattern. Both pattern devices attach to the left side of the carriage and engage with the grooves of the knitting bed to work. Patterns are created via a drum. The super auto has a drum with 4 disks and the Super 8 has a drum with 8 disks. Each disk is configured with a different pattern to rotate and engage with the needles. In the image below, just under the engraved number 8 is an example of one of the pattern disks. It and 7 others are sitting on a drum which can be rotated left or right. Lets say you select disk 8, followed by disk 5, followed by disk 2, then followed by disk 1. You have just created a pattern. Using the accessory below, you can create a record of your pattern. It is essentially a printout of your pattern which advances like a typewriter to tell you which disk to select, which row you are on and any cam changes. Ingenious. See here how the device with your pattern written down, interacts with the pattern accessory. I have it working and will make a video soon! These devices are capable of many type of knit structures including a variety of jacquards and fairisle. I've included a sample I created using the Super 8. As you can see each time I move the pattern drum to activate a new disk, a new pattern is generated. I tried a basic jacquard structure here. To begin, I start on the right hand side of my knitting, I select a pattern disk and run it and the carriage set for rib across the bed to select needles. Then on the left hand side I knit the selected needles back into position. Where the black yarn is on the sample, that is a rib knit. That is followed by a row of the cream knit in a tube. On the back you can see alternating black and white stripes where I knit one row of rib and one row of tube. In some places I was playing around with lengthening the pattern just by adding rows of rib so that is why you see some thicker blocks of cream yarn. The really interesting thing is how much flexibility these pattern devices would have offered the user, because they really are so ingenious. The super auto essentially selects new high butt positions for each row, which is really unique. Todays machines develops patterns through a combination of high and low butts in fixed positions and carriage cam changes. To add to the ingeniousness of this device, you can also do some freestyle jacquard intarsia type of work. The image below shows an example. You can run the carriage across the needle bed, and select your own needles by putting them into working position thus creating your own large scale coloured designs. I have some more great vintage images to share. These are all from 1929 from the Dubied magazine publication "Lavori di Maglieria." I'll be posting more from this collection in the coming weeks. I just love the knitted coats!

My fall season went really well. I did more craft shows, both local and far away which I found both refreshing and rewarding. I'll definitely do more next year. In addition I picked up some more vintage machines which have some great features such as patterning capabilities. Its been busy at HQ working on orders and feeling Fall Vibes but I wanted to fill you in on upcoming events and shows. I'll be at the Beehive Winter Fair on November 28th-29th here in Hamilton. It has a solid line up of skilled crafters with some amazing work as well as the Halifax Winter Market on December 4, 5 and 6th. I'll be at both shows with my mittlets, scarves and sweaters. I found time over Thanksgiving to get home to the farm and enjoy a more rural pace. Dad is resurfacing the barns and organizing his clock restoration workshop so it was great to see that happening. I also did some store updates here and have been working on improving the overall vibe of my product photos. I've posted some photos on the blog below. I feel better about this new style of photos, they are still clean and clear but a bit more interesting. Thank you so much for your amazing positive responses so far! Speaking of positive feedback, check out this fabulous post here from Tracing Threads, it is so nice to hear my garments become well loved and appreciated!  I've also been shuffling my space and workshop about, and just focusing/ narrowing my knitting interests. It can be hard with so many possibilities especially on these old machines:) I'm particularly interested in developing pattern work on the Dubied's. There are some really unique punchcard, prisms and pattern disks out there and I'm hoping to share this work with you shortly.

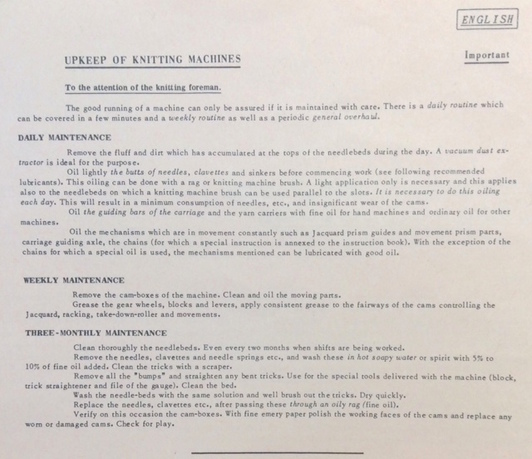

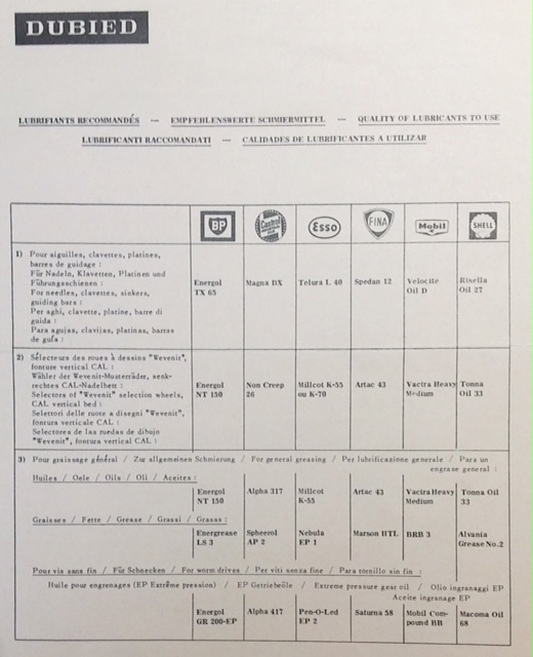

Hop on over here to view my Fall collection. I'm pretty excited about it. Specifically the use of lace and mesh in sleeves of the winter sweaters and the use of marls for stripes in my accessories. With my recent acquisition of a cone winder I've been able to ply yarns together for a salt and pepper marl. As well as achieve some great mixes, such as black linen with black cashmere and viscose for fine gauge sweaters. In other news I found these great pages on machine maintenance. Click on them to magnify so you can give them a good read. My manuals are not too helpful on the subject of maintenance so this detail on daily, weekly and three monthly maintenance is very welcome. The second page gets really specific about oil types from specific brands. I can't help but feel this is more about back office corporate deals and arrangements than it is about real world oil brand usefulness. I have always used clear sewing machine oil on hand flat knitting machines from my local dealer and it has worked just fine. When using flat japanese style knitting machines I use either Ballistol oil or a spray on silicone lubricant. Do you have any preferred brands???

I was recently contacted by Vivian down in Ft. Lauderdale, Florida. Her mother is from Northern Italy and brought this machine along with her to America. I wanted to post about it because all together it is a fantastic machine to knit on. So yes, its for sale! and if you are located in the States, looking for a basic high quality machine, I highly recommend this. It is a gauge 7 ( 7 stitches per inch) machine with a metre long bed. Its not a machine with high and low butts, but it does do ribs and tubes and stockinette. The machine comes with Italian manuals, all of its cast on combs, weights and transfer tools. It also comes with a Super-Otto accessory for patterning (which I have never ever seen complete with a machine) and if that wasn't enough there is a cone winder and skein winder. For me the thing that makes this machine is the patterning Super-Otto accessory and the completeness of the accessories. The Super Otto accessory is a rotating drum which attaches to either side of the carriage, selecting needles for colour jacquard patterns. I like to see good machines go to good homes so please feel free to contact Vivian about this machine here. If it has sold I will update my post to reflect that. If you purchase it, contact me and I will send you an English knitting manual to help you along. In other news, I've been installing Margarita's Dubied machines and her old Moretto. Its been really overwhelming keeping track of the parts, restoring them and sorting out electrical work for plugging in the motorized machines. The manuals for the complex machines like the DUT and Moretto have been amazing to parse.

When we first got the machines back, some of them needed testing. So I left those at my parents' farm an hour outside Hamilton. My dad got the electrical connections tested and parts replaced. Then we carted them over here on a large flat bed trailer and got them moved in JUST BEFORE A THUNDERSTORM ROLLED THROUGH! Today I got the 220v plugs for the machines sorted out, but not before one of the electricians cut through a water line spraying half of my stainless steel machines with tap water. Cue the flailing hands and the visual of a knitter running with an oil can. One of these 'new' machines is missing its motor and the DUT is completely missing its jacquard prism and its set of punch cards. I think we can make the jacquard prism (if that sounds crazy its just a set of perforated metal bars) and the punch cards should not be too hard. There's a level of archaeology that meets technology here which I fundamentally enjoy. There are so many ways to select a needle or particular stitch type on a machine. Its really endless! I recently acquired a colour Dubied manual in Spanish. If you have previously purchased the English PDF version from me please email me. I can send you this Spanish version so you have the benefit of crisper detail and colour images. This is the same edition, just a different language. In future I will be offering them together to increase usefulness.

|

Anna is a Hamilton based knitwear and textile practitioner blogging about her collection development as well as pre-1950's knitwear technology.

Links

Emma Gerard Make something bookhou Iben Hoej krystalspeck workshop bespoke truckee amy lawrence designs Categories

All

|

RSS Feed

RSS Feed