|

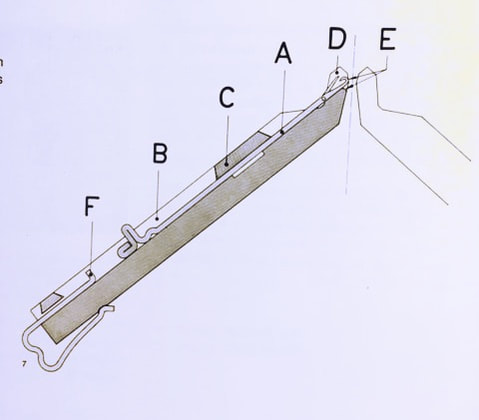

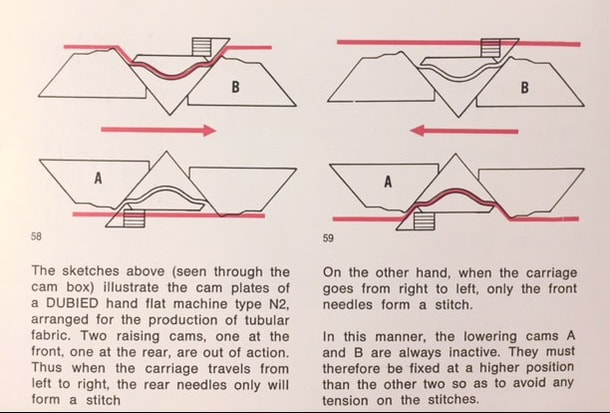

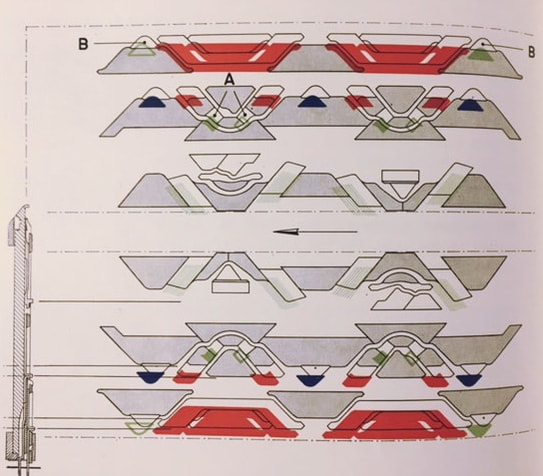

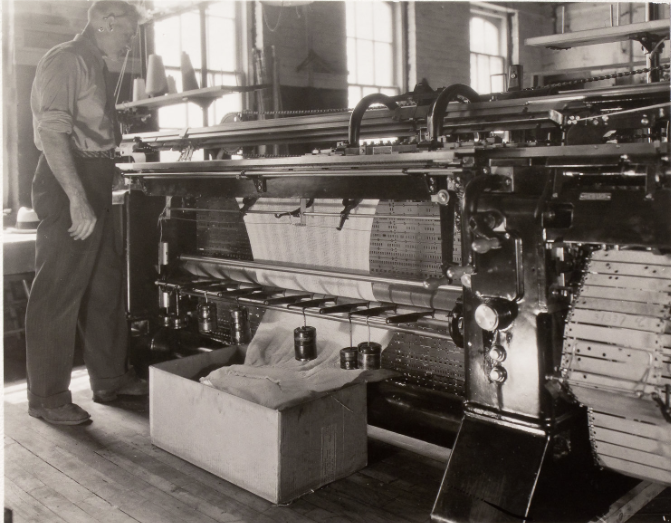

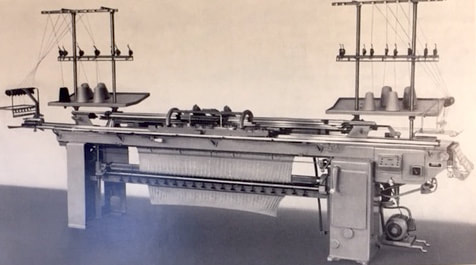

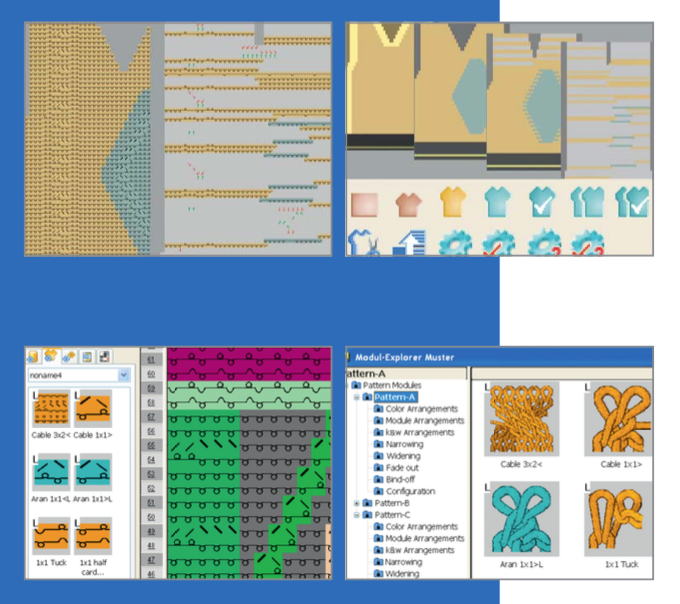

Im exploring the world of computerized knitting machines from a hand flat background and it can be very mystifying at times. I spent some years considering analog but motorized stoll/ shima/ dubied machines from the late 1970’s. These machines used punchcards, prism mechanisms and drums to create patterns (or direct the needles into pathways to create patterns). I have collected the Dubied DUT which is missing a key pattern device, I have a Moretto with a worn out motor and take down device (with auto cam!). I use this machine as a hand flat and it is so reliable. As well, I have the Super-8 mechanism (it has a habit of slipping though like a stripped screw so the pattern gets all jumbled up). The diagrams below show the basic difference between a Dubied N2 cam carriage and a more complex computerized one: there are more available paths for the needles to create more complex stitches. (Many of the diagrams are pulled from a book called "dubbed Knitting Manual. It is a hardbound book that examines the stitch structure of knitted pieces and explains it in structures similar to how modern knit software looks.) In terms of semi industrial machines that are also double bed there are (or were) the passap e6000, e8000 as well as the brother ck35. These 90’s era machines potentially have interface issues with software and modern computers. Venturing further into domestic machines the brother 900 series machines with a ribber attachment can accomplish many textures and patterns on the machines’ computer. All of these machines whether domestic or industrial have a maximum speed measured by ‘stitches per meter’ (or m/s) that is effected by: whether its motorized or not, the type of pattern produced, how many colours per row, the width and size of the piece to be produced and the gauge. Many modern industrial machines have a top speed of 1.0 m/s which is insanely fast. I think this top speed would be for a stockinette in one colour and only using one bed to knit. As you add more colours and complexity your speed will be reduced. Overall, my interest in industrial machines is about increased complexity and production. Right now I produce everything on hand flats which can take many hours. I love the feel and build quality of hand flats but not the speed. Some brands that make computerized machines are : Stoll, Shima seiki, Steiger, Protti, Universal, and Shine Star. Once you get into specialty machines there are ever more brands. There are sock machines, glove machines, toque machines, circular machines for mattress covers, industrial filters, shoes, and medical supports. But we are getting ahead of ourselves. This is about computerized machines that will do basic jacquards, basic programs and how to use them. Ive found some classes for Stoll here which is in a college setting in North Carolina. But really Stoll (and Shima Seiki) offer classes around the world in many major cities. For example, New York has a salesroom for Stool but they will also demonstrate the software for you. There are also comprehensive classes in Frankfurt, Germany. This week long class primarily exposes you to the M1 Plus software that builds files for Stoll machines then you knit out your piece on the machine. The program recommends that you have experience on hand flats before taking the class. If you look at knitting patterns for hand or machine, its about actionable steps in generally a grid formation. This program takes that concept to a higher level…with more actionable steps. To be continued.

2 Comments

5/12/2019 02:04:17 am

Hello - it's so great to come across your blog! I too am exploring computerised / industrial machines, coming from a hand flat background. What a fascinating journey, right?!

Reply

Leave a Reply. |

Anna is a Hamilton based knitwear and textile practitioner blogging about her collection development as well as pre-1950's knitwear technology.

Links

Emma Gerard Make something bookhou Iben Hoej krystalspeck workshop bespoke truckee amy lawrence designs Categories

All

|

RSS Feed

RSS Feed